Andy Green’s Diary – Summer 2018

As the UK continues to turn brown and curl up at the edges, we’re having a busy summer of (very hot) public events across the country.

As the UK continues to turn brown and curl up at the edges, we’re having a busy summer of (very hot) public events across the country.

In the first of a regular series of articles about our sponsors, we hear from Innoval Technology – one of the BLOODHOUND Product Sponsors working on the Car’s desert wheels – about why and how it is involved in the Project. Innoval also explains how you choose the right materials for such hard-working wheels and what’s going to happen next….

Engineering progress on the Project remains slow, as we focus our efforts on getting the funding together to run the Car next year. The good news is that we’re generating more and more interest, as global companies look at our fully-assembled Car and ask the question we want to hear: ‘How do I get involved?’.

BLOODHOUND’s high-speed desert wheels each weigh 95 kilogrammes. They not only have to carry the weight of a 7.5-tonne car, but also must not fall apart when spinning at over 10,000rpm and subject to a force of 50,000g at the wheel rim.

As we get closer to completing the most extraordinary straight line racing car in history, it's easy to forget the most important part of building the world's first 1000 mph Car.

'The design is pretty much done, now we’ve just got to assemble it'. Mark Chapman was sounding confident at our recent 1K Club open day.

My first photo (above)…it’s like a scene from a deep space science fiction movie, isn’t it? But this isn’t science fiction, it’s science fact!

It was great to see the cockpit finished and unveiled in public this month. This is my ‘1000 mph office’, which I first started to design over 6 years ago. It’s been exciting to see it come together, but as the design of the Car became more detailed, I’ve had to change some of the requirements as we went along. I’m thrilled and – I can now finally admit – slightly relieved that it does all fit in the space available.

Let me tell you about the goat’s head that’s worth more than a garage full of your favourite supercars….

This particular ‘goat’s head’ is actually the hardest working, land-based vehicle suspension component in human history!

As a team we have a good or bad habit (depending on your viewpoint) of giving key assemblies for Bloodhound SSC nicknames.

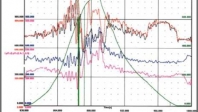

‘Data is key to pushing the boundaries – work out what you need and build it in from the start’. That was the advice we got from former NASA astronaut Neil Armstrong when he visited the BLOODHOUND Technical Centre back in 2010. This was very much our plan, but it was great to hear it confirmed by the first man to walk on the Moon. The reality seemed a long way off at the time, but suddenly it’s here and we’re building the sensors into BLOODHOUND SSC.