Adapted from an article by Ben Evans and Mark Chapman

The jet intake in BLOODHOUND SSC delivers the flow of air from the 'freestream' ahead of the Car to the first stage of the Eurojet EJ200 jet engine in a way that means the engine will perform well and at maximum efficiency.

The design of the intake duct is important because its size and central positioning is one of the main reasons that the rest of the Car looks like it does.

This page describes how the BLOODHOUND Team worked out what size and shape the intake duct should be, and where it should be in the Car to make the EJ200 jet engine work as efficiently as possible.

Airflow quality

The key aspect is the ‘quality’ of the airflow delivered to the jet engine via its intake duct, which can be measured in terms of a simple set of variables. These include:

- 'Total pressure distortion' – How big are the variations in the total pressure (or total energy)? This is measured across a plane slightly upstream of the engine compressor face.

- 'Swirl' – What is the mean deviation from a purely axial flow upstream from the compressor face?

- 'Flow stability' – How much will the flow in the duct fluctuate?

All of these quantities vary with 'mass flow rate' through the duct – or, strictly speaking, a 'mass flow function' (controlled by Andy using the throttle in the cockpit) which varies according to the mass flow rate, pressure and temperature. Analysing how all of these variables change as the Car travels at different speeds is complex, but is possible using a technique called 'computational fluid dynamics' (CFD).

Initial intake design

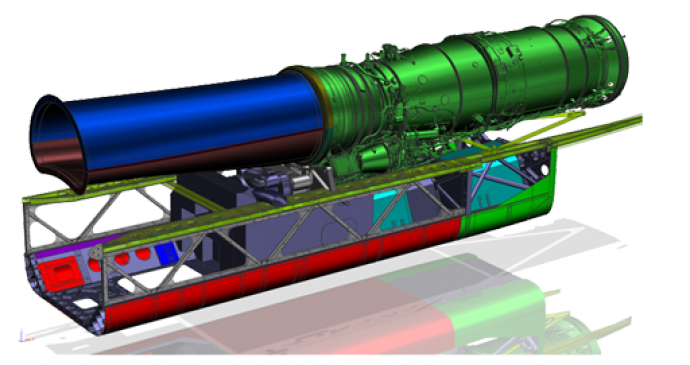

Initially, the concept developed by chief aerodynamicist Ron Ayers and Glynne Bowsher was that BLOODHOUND would have a twin intake ‘bifurcated’ duct (figure 1).

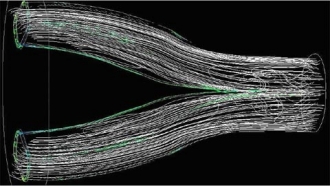

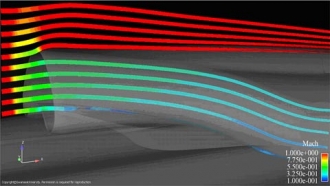

However, it quickly became apparent that achieving a stable, smooth flow through this arrangement was not straightforward, as shown in the highly turbulent flow pattern through the bifurcated duct modelled in figure 2.

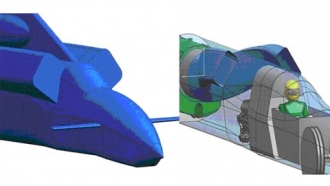

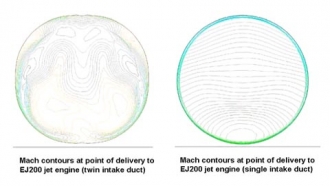

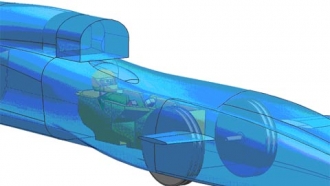

As a consequence, the design was changed to a single intake duct configuration, with the intake positioned above the cockpit canopy (figure 3). CFD showed this would massively improve the quality of airflow arriving at the engine compressor face (figure 4).

Matching the intake with the rest of the Car

Ultimately, the overall shape of the Car has been determined by the need to et the correct flow of air to the engine, both in terms of speed and steady flow. That's because the external air flow around the vehicle and the internal duct flow are closely coupled. The geometry of the nose and cockpit canopy are vitally important in terms of delivering the air supply efficiently to the EJ200 jet engine.

Ultimately, the overall shape of the Car has been determined by the need to et the correct flow of air to the engine, both in terms of speed and steady flow. That's because the external air flow around the vehicle and the internal duct flow are closely coupled. The geometry of the nose and cockpit canopy are vitally important in terms of delivering the air supply efficiently to the EJ200 jet engine.

In simple terms, the trick is to expand the airflow quickly (to slow down the velocity) and then turn it late with the slower flow.

But in practical terms, what does this mean?

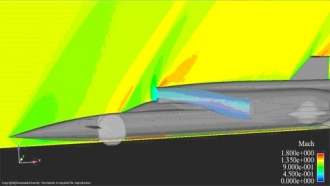

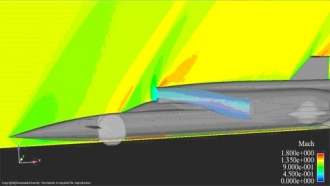

Firstly, to slow down the airflow, the shape of the cockpit canopy and intake have been designed so that at supersonic speeds a two-shock system is set up ahead of the duct. This decelerates the flow to the subsonic speeds necessary for the jet engine's intake duct, while minimising losses in total energy and maximising engine performance (figure 5).

Then, the simplest way to steady the flow is to make it turn more gradually. Our engineers worked out that this could be done in three ways:

Push the engine further back in the Car, which in turn will increase the length of the duct and therefore make the bend shallower. This could be done up to a point, but moving a tonne of engine further back in the Car is bad for weight distribution, and would need to be matched by an increase in the wheelbase.

Push the engine further back in the Car, which in turn will increase the length of the duct and therefore make the bend shallower. This could be done up to a point, but moving a tonne of engine further back in the Car is bad for weight distribution, and would need to be matched by an increase in the wheelbase.- Raise the engine in the Car to straighten the duct. However, this would reduce the Car's stability as the engine would now sit higher and make the Car more top heavy.

- Lower the driver. The original seating position in BLOODHOUND was based on the design of Thrust SSC, but by sitting Andy lower in the Car the duct height could be reduced, which has the same effect as raising the engine but without the impact on stability.

Where should Andy sit?

To test its effectiveness, the last option was taken to its most extreme in the Team's designs. This showed greatly improved flow to the engine, but at the expense of Andy's comfort and visibility –infact, he would have been sitting so low that the front body would need a deep scallop for him to see between the front wheels (figure 6).

In order to let Andy have a more upright seating position, a 'parametric' study looked at different combinations of intake aspect ratios, offsets and ways of controlling the expansion of the flow, and this led to the inside of the duct being reshaped.

Intake shape and size

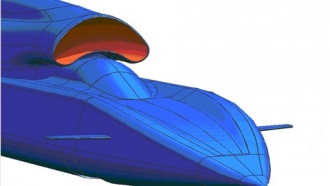

All of this work was based on a rectangular duct, as this simplified the analysis. The next stage was to use a duct whose shape matched that of the intake canopy. This more triangular shape (figure 7) actually helps the flow around the bend of the intake and from an external aerodynamics perspective it looks much neater.

All of this work was based on a rectangular duct, as this simplified the analysis. The next stage was to use a duct whose shape matched that of the intake canopy. This more triangular shape (figure 7) actually helps the flow around the bend of the intake and from an external aerodynamics perspective it looks much neater.

The final stage was to match the intake size to the engine design. The engine can only gobble up the air at a certain rate, so if the intake is too large, then at higher speeds excess air will spill around the outside of the intake causing drag. However, if you match the intake size solely for high speed operation, then at low speeds the engine will be starved of air, and won't be able to operate at full power.

In the final design, the intake has been optimised for Mach 1.1.

The duct shape not only influences the engine performance and external aerodynamics, but also how other components are packaged within the Car. The area under the duct is the only space available to put the auxiliary power unit and the HTP and jet fuel tanks. In the end, compromises were made in the duct shape and the flanks of the Car have were enlarged slightly to maintain the volumes required.

Push the engine further back in the Car, which in turn will increase the length of the duct and therefore make the bend shallower. This could be done up to a point, but moving a tonne of engine further back in the Car is bad for weight distribution, and would need to be matched by an increase in the wheelbase.

Push the engine further back in the Car, which in turn will increase the length of the duct and therefore make the bend shallower. This could be done up to a point, but moving a tonne of engine further back in the Car is bad for weight distribution, and would need to be matched by an increase in the wheelbase.