Wheels

Bloodhound SSC Vehicle Technical Specification: configuration 11, June 2012

Wheels

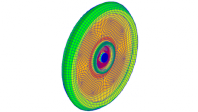

Lockheed Martin UK is providing Research & Development in the first step towards designing the wheels on the world’s fastest car, BLOODHOUND SSC.

Lockheed Martin is leading a 700 hour ’wheel concept study’, to identify and explore initial ideas for the wheel design, which, made from premium grade solid titanium, will experience the most extreme driving conditions ever known:

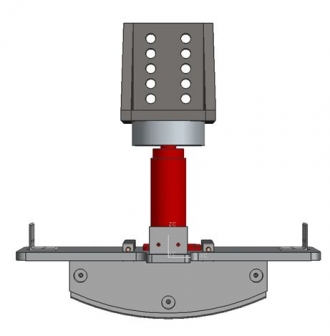

The BLOODHOUND Project, Britain’s 1,000mph land speed record attempt, announced today that wheel bearing manufacturer Timken will be sponsoring the wheel bearing solution for the BLOODHOUND SSC (Super Sonic Car).

Timken has been working closely with the BLOODHOUND Project design team to produce a solution for the bearing challenge. Timken has already delivered the first three car sets of bearings for validation testing and runway tests and will continue to work closely with team.

The roller coaster that is Bloodhound SSC certainly has its ups and downs, but my feeling for April is that we had a month very much on the up! - With the last few days of the Month delivering in spades.

by Andy Green

by Brian Coombs

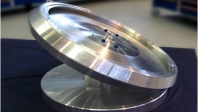

The wheel is a very complicated component. It has to cope with very high loads applied to it, and has many other constraints imposed on its design.

When we started our design work, we did not know where we were going to be running, or even what the surface would be – salt as on Lake Eyre in Australia or playa as at Black Rock in USA. Our design was therefore based on the data we had from Thrust SSC and started with a wheel that was 900mm in diameter and 150mm wide, which we thought would have to be made of titanium.

Wheels with up to 5 tonnes of force rotating at 10,000rpm are going to have some sort of effect on the ground they are running on. What that effect will be though is something that has never been investigated before.

with up to 5 tonnes of force rotating at 10,000rpm are going to have some sort of effect on the ground they are running on. What that effect will be though is something that has never been investigated before.

On the 30th April, we announced our wheel manufacturer, Castle Precision Engineering, who will take on the manufacture of both the UK runway and desert wheels. and we took the full size show car to their site to introduce the project to their workforce.

Today, at Holyrood, BLOODHOUND SSC’s driver Andy Green and the Institution of Mechanical Engineers announced that Glasgow firm Castle Precision Engineering Ltd is to produce the wheels for the 1,000 mph world Land Speed Record car.

When the Car is complete, BLOODHOUND will have two sets of wheels: desert wheels for use in Hakskeenpan for the land speed record runs and a separate set of runway wheels