by Andy Green

In some ways, building a Land Speed Record Car is very simple. All you have to do is build it with enough power and low enough drag, and it will get to 1000 mph. Keep the aerodynamic lift/download changes small, and the Car will stay on the ground. Then you just need to build a structure that is strong enough to support all the loads (for BLOODHOUND, that’s 135 000 hp from the jet and rocket, and 12 tonnes of air load per square metre of bodywork). But there is one big difference from ‘conventional’ supersonic vehicles (i.e. jet fighters) – BLOODHOUND SSC has wheels. At 1000 mph, BLOODHOUND’s wheels will be rotating at 10 000 rpm and the wheel rims will be pulling 50 000 G.

With the help of Lockheed Martin (UK), we’re designing an aluminium wheel that will cope with these loads. Unfortunately, that’s not quite the end of the task for the wheel design, as Hakskeen Pan is covered in stones. We are tremendously lucky to have the support of the Northern Cape Government in preparing the desert surface and 300 local workers will be removing stones by hand over the next few months. But there is always the chance that there are small stones buried just under the surface that no-one can see.

It is very unlikely that the front wheels would flick one of these stones up as BLOODHOUND SSC tears across the desert at 1000 mph, and even more unlikely that one of these kicked-up stones would hit one of the rear wheels. It’s very unlikely indeed – but it could happen. A stone strike at 1000 mph would produce the same impact as a bullet – so we literally need to design ‘bullet-proof’ wheels.

It is very unlikely that the front wheels would flick one of these stones up as BLOODHOUND SSC tears across the desert at 1000 mph, and even more unlikely that one of these kicked-up stones would hit one of the rear wheels. It’s very unlikely indeed – but it could happen. A stone strike at 1000 mph would produce the same impact as a bullet – so we literally need to design ‘bullet-proof’ wheels.

We are currently assessing 2 different aerospace-grade aluminium alloys for the wheels, with the expert help of Innoval. The choice is between Al2014 and Al7075, for those of you who are interested, and this test should also show if one is better than the other at resisting stone impacts.

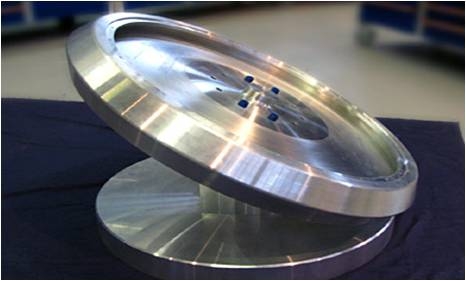

Picture right: Cavendish Laboratory – Loading the Gas Gun

Now comes the tricky bit. How do you fire stone samples at 1000 mph at aluminium samples and measure the results? The answer is to use a gas gun – in this case, at Cavendish Laboratories in Cambridge. Small stone samples from Hakskeen Pan were mounted on a ‘sabot’ (a cylinder that will carry the stone sample and allow it to be fired from the gun).

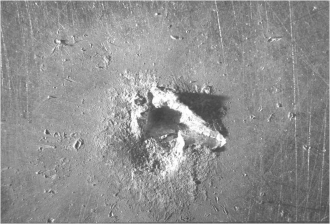

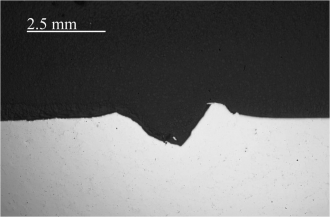

The stone samples were fired at 1000 mph at samples of both our aluminium alloys. The impacts were filmed with a very high speed camera (and I mean very high speed – a picture every 20 millionths of a second!) and the samples analysed afterwards. As you can see from the pictures, the damage caused by a 5 mm cube of Hakskeen Pan stone is pretty severe. Innoval is now checking the micro structure at the bottom of the impact craters, to see if there are any differences in the 2 materials at a microscopic level.

Photographs every 20 millionths of a second show the stone impact

Pictures above: The stone impact crater in close-up and cross section – some serious damage

So what would this damage do to a wheel at 1000 mph? This is the bad news – with this much damage, the wheel would probably fail, leading to the world’s fastest-ever car crash. That’s not good. So is this a major problem for BLOODHOUND? Not really – as ever, the engineering team is already working on the answer. When we design the rear wheel fairings, we will need to include a ‘ballistic shield’ (which in this case is a fancy name for a steel mudguard) to protect the wheels from the (very unlikely) possibility of a stone strike.

Has this test helped us choose the alloy for the wheels? Not yet. The initial test results did not show a significant difference in impact damage, so we will choose our preferred alloy based on other criteria. The test was still very worthwhile though, as we now know what we need to do to protect the wheels at high speed. One more technical question resolved, one step closer to 1000 mph.