Wheels with up to 5 tonnes of force rotating at 10,000rpm are going to have some sort of effect on the ground they are running on. What that effect will be though is something that has never been investigated before. Experiments then need to be undertaken that balance between the wheel and the surface - we need to understand what the shape of the keel will do both to the ground and the wheel itself. To do this, a ground test rig is being constructed to be taken to the possible run locations...

with up to 5 tonnes of force rotating at 10,000rpm are going to have some sort of effect on the ground they are running on. What that effect will be though is something that has never been investigated before. Experiments then need to be undertaken that balance between the wheel and the surface - we need to understand what the shape of the keel will do both to the ground and the wheel itself. To do this, a ground test rig is being constructed to be taken to the possible run locations...

What is it?

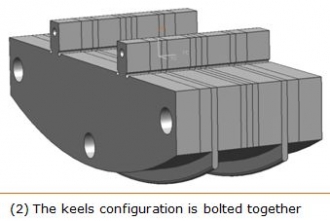

Instead of manufacturing several variants of the BLOODHOUND wheels to test on location, the test rig utilises a modular approach. A segment of the wheel is constructed using different thickness plates and then bolted together. This allows for several keel configurations to be trialled quickly and efficiently.

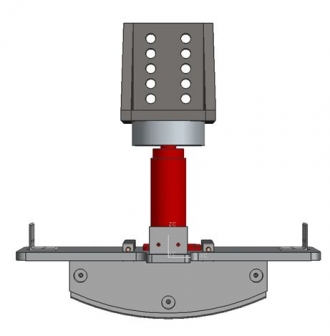

To understand what effect these different layouts may have on the ground surface, the section of the wheel (in whichever configuration is being tested) is pushed with increasing pressure vertically downwards and the deformation is recorded. This is done using four depth gauges that are secured on the four sides of the rig.

To understand what effect these different layouts may have on the ground surface, the section of the wheel (in whichever configuration is being tested) is pushed with increasing pressure vertically downwards and the deformation is recorded. This is done using four depth gauges that are secured on the four sides of the rig.

So, how exactly does it work?

So, how exactly does it work?

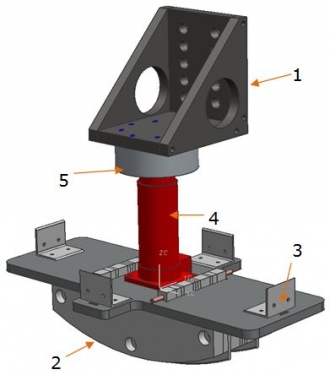

Firstly, the entire rig is secured to the axle of a truck (1 right, and picture below). This provides enough of a weight resistance to stop the rig from lifting during testing.

The keels (2) are then placed on the track surface and height measurements taken at the four points around the rig (3). This can then be compared to as the pressure increases (and subsequently can be used to plot the deformation vs. load).

Using the bottle jack (4) and the load cell (5), the force on the wheel segment is increased incrementally whilst the measurements are taken from the four points. This will show not only how far the wheel is going into the ground with what force, but also whether it will go in straight or on a slant.

Once the pressure on the wheel has reached 5 tonnes, the rig can be reset and driven to another location further down the proposed track. The benefit of the modular wheel setup is that any keel arrangement can be constructed and easily pinned onto the shoe plate, allowing for the test to be conducted with different shapes, sizes and configurations to determine the optimum profile of the wheel.

When this rig is used, it will give us a good view of what the wheel shape will do to the ground and vice versa, helping us to get the optimum shape for a wheel that will spin 166 times a second.

The test rig was produced almost entirely under Product Sponsorship - our thanks go out to :