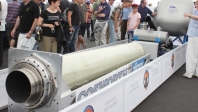

BLOODHOUND SSC will use rockets when it breaks the World Land Speed Record. These will sit at the rear of the Car, below the Eurojet EJ200 jet engine, but we will use different ones when running the Car at 800mph and 1,000mph.

For the 800mph runs the Car will have a single monopropellant rocket, whereas in the 1,000mph Car there will be a cluster of three hybrid rockets. Both designs are being provided by specialist Norwegian company Nammo.

In order to accelerate the Car to 800mph, the monopropellant rocket will produce around 40kN of thrust and the EJ200 jet engine will make 90kN in reheat. For the 1,000mph runs, the Nammo hybrid rockets will provide a thrust of 123.75kN, generating about 212kN in total – that's eight times more power than all the cars on a Formula 1 starting grid combined!

History of BLOODHOUND’s rocket

Initially, BLOODHOUND was intended to be purely rocket-powered. This would have offered certain performance advantages, but the jet engine was added as these are easy to throttle and will enable much of the ‘low speed’ testing – the Car can be run at up to 600mph using the jet engine alone.

The Nammo rocket will be used instead of the Falcon Project rocket which initially proved the concept of using an internal combustion engine to pump oxidiser into the rocket in the Car.

Design

The Nammo rocket is a ‘hybrid’ design. This means that it uses a combination of propellants – in this case high test hydrogen peroxide (HTP) as the oxidiser and synthetic rubber as the fuel. Hybrid rockets like this are safe and controllable, as well as being lower cost and greener than alternative methods.

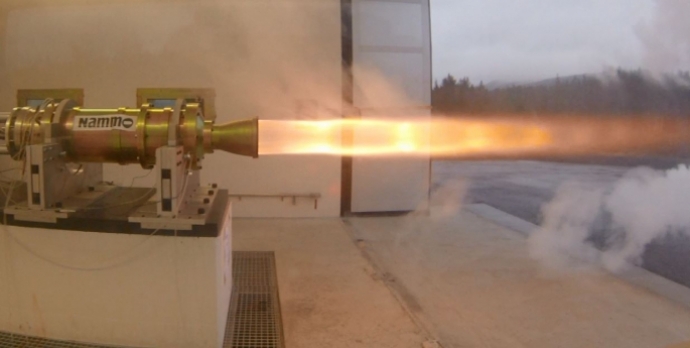

In the Nammo rocket, the HTP is forced through a silver-plated catalyst pack at extremely high temperatures and pressure (around 70 Bar [1,000lb/sq in] at 40 litres per second). Triggered by the catalyst pack, the peroxide, which chemically is H2O2, decomposes into steam (H2O) and oxygen (O2).

This process releases a lot of energy, so that the mixture emerges at around 600°C into the combustion chamber where its extreme heat ignites the fuel. The O2 (oxygen) feeds the fire, making the chemical reaction more vigorous and producing more thrust. This, in turn, heats up to around 3,000°C (twice the temperature of a volcano) and is forced out through a nozzle to produce thrust.

The design of the Nammo rocket is still being finalised, but for the 1,000mph runs it is likely to have a cluster of three or four motors rather than a single large combustion chamber.

The rocket being developed by Nammo for BLOODHOUND will one day power the next generation of European Space Agency (ESA) satellite launchers.

Safety

The rocket oxidiser – HTP – is very reactive, so all the parts of the Car which will come into contact with it have been made of non-reactive materials and have to be ‘passivated’. This means that they need to be pickled in an acid bath to make them inert and remove any possible contaminants that may react with the HTP.

The plumbing also needs to be very good quality to avoid leaks and all storage devices have been carefully made and treated.

Find out more

The rocket doesn’t work in isolation. Find out about:

Find out how hybrid rockets work in our Cisco BHTV episode.

See how the Nammo rocket performed in tests in December 2014, with an explanation of how this hybrid rocket works.