Press Release from the Goodwood Festival of Speed, 1st July 2011

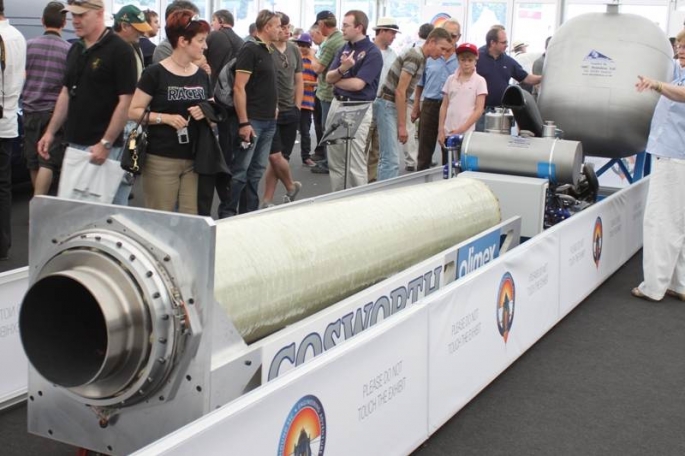

Today, at the world famous Goodwood Festival of Speed, The BLOODHOUND Project displays for the first time the complete rocket propulsion system for their 1000mph Land Speed Racer. Comprising of a custom-designed Falcon hybrid rocket, Cosworth CA2010 F1 engine, pump adapted from the Blue Steel cruise missile and one-tonne capacity HTP oxidiser tank, the system will be soon be tested for the first time in what will be the largest rocket firing in the UK for 20 years.

The BLOODHOUND Project is an international education initiative focused on a 1,000 mph World Land Speed Record attempt. Its aim is to inspire the next generation of scientists, engineers and mathematicians by demonstrating these subjects in the most exciting way possible.

At 4m (12 feet) long, 45.7 cm (18 inches) in diameter and 400kg in weight, the Falcon Project Ltd rocket is the largest ‘hybrid’ ever developed in the UK. Designed by self-taught Manchester rocket engineer Daniel Jubb, 27, it will provide 27,500lbs thrust – equivalent to 77,500thp, or 645 family saloons, and work in unison with the car’s EJ200 jet engine to power BLOODHOUND from standstill to 1050mph in just 45 seconds.

The term ‘hybrid’ stems from the fact that BLOODHOUND’s rocket combines solid fuel with a liquid oxidiser, High Test Peroxide (HTP), to create its power. Although technically demanding, this approach is the safest and most controllable with driver Andy Green able to shut off the flow of oxidiser and extinguish the rocket if required. Safety is further enhanced by the use of HTP as the oxidiser; a staple of the UK’s rocket programme in the 1960’s and 70’s, it is relatively benign to store and handle and has an excellent safety record.

In early tests, small (6”) versions of the Falcon rocket produced excellent power outputs from the very beginning and the on-going development of Daniel’s design is being closely monitored by the international rocket community, including NASA. In a recent feature, New Scientist magazine even speculated whether BLOODHOUND SSC’s rocket might lead to safer space travel…

In early tests, small (6”) versions of the Falcon rocket produced excellent power outputs from the very beginning and the on-going development of Daniel’s design is being closely monitored by the international rocket community, including NASA. In a recent feature, New Scientist magazine even speculated whether BLOODHOUND SSC’s rocket might lead to safer space travel…

The full rocket system will be tested at a UK location, to be announced, later this summer. It will mark the most significant technical milestone in the BLOODHOUND programme to date and a remarkable achievement for a small team of highly skilled, innovative and passionate British engineers.

“Seeing the rocket, Cosworth F1 engine and HTP tank next to the model of the BLOODHOUND SSC here at the Festival of Speed is very exciting,” said Mark Chapman, Chief Engineer. “Firing it up later this summer will be an amazing experience – one we’re looking forward to sharing with schools, fans and followers around the world.

The development of such a large rocket has been an enormous challenge and we are grateful to have the support of outstanding technical partners, including Cosworth, Dragonfly Technology Ltd, QinetiQ and Intel. Not forgetting, of course, The Falcon Project Ltd, for creating a world class prototype rocket, specifically for BLOODHOUND SSC.”

BLOODHOUND SSC: The Rocket System in Detail

BLOODHOUND SSC’s rocket will burn for 20 seconds during each high speed run, during which time it will consume 181 kg’s of solid fuel and 963 kg of oxidizer to produce 122 kN (27,500 lbs) peak thrust (equivalent to 77,500hp, or the combined power of 645 family saloon cars).

This will be in addition to the 90 kN (20,000lbs) of thrust provided by the car’s other main engine – a state of the art EJ 200 jet from a Eurofighter. Together, they generate more power than 180 F1 cars, making the BLOODHOUND SuperSonic Car the most powerful land vehicle ever created.

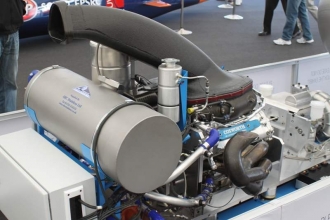

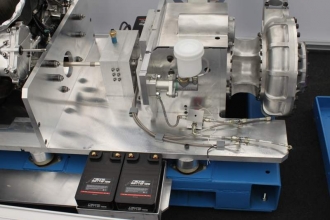

Right: The Cosworth CA2010 V8 engine with its ice tank on the rocket rig

Right: The Cosworth CA2010 V8 engine with its ice tank on the rocket rig

There are five main elements to the system on display at the Festival of Speed: the combustion chamber, the solid fuel, the liquid oxidiser and the oxidiser pumping and control system. The rocket itself consists of a solid fuel made from synthetic rubber (HTPB, or Hydroxyl-Terminated Polybutadiene, similar to that used in aircraft tyres) with metal powders and burning rate modifiers added to the mix. This is contained within a composite case which will be slung underneath the EJ200 jet engine. This will be replaced after each run using torpedo-loading technology.

Just as the car design team made extensive use of computational fluid dynamics (CFD) to predict airflow over the aluminium and carbon skin of BLOODHOUND, so Daniel’s seven-strong team used CFD to model the flow of gasses inside the rocket. They then optimised its performance by varying the composition and geometry along the length of the solid fuel grain. The result is a hybrid rocket of world-beating power and efficiency.

Left: The reduction gearbox, clutch and fuel pump on the rocket rig

Left: The reduction gearbox, clutch and fuel pump on the rocket rig

High Test Peroxide (HTP) is the liquid oxidiser used to burn the solid fuel. A staple of the UK rocket programme during the 1960’s and 70’s, HTP is non-toxic and relatively safe to handle. This makes it the ideal choice for use in a Land Speed Record car that will be refuelled in a desert environment during a record attempt.

The need to deliver 963 kg of liquid HTP in to the rocket in a mere 20 seconds presents a significant technical challenge in its own right.

BLOODHOUND’s solution takes the form of a Cosworth CA2010 Formula 1 engine, one of the most reliable on the grid, mounted to a pump from a 1960s’ Blue Steel cruise missile. Upgraded by the original designer, our pump is now 15% more efficient that its airborne predecessor and able to convert the 800 bhp produced by the V8 race engine into 1100lb/in2 (76 Bar) of pressure and a flow rate of 105 lb/sec (47.6 kg/sec) – enough to fill a bath in three seconds.

A 1,000 mph run…

Prior to commencing a high speed run the Cosworth engine (also known as the Auxiliary Power Unit or APU) will be started and left idling at between 3000 and 4500rpm. The oxidiser tank will also be pressurised to 24psi using inert nitrogen gas.

Prior to commencing a high speed run the Cosworth engine (also known as the Auxiliary Power Unit or APU) will be started and left idling at between 3000 and 4500rpm. The oxidiser tank will also be pressurised to 24psi using inert nitrogen gas.

With the car accelerating under the power of the EJ200 jet engine alone, Andy will engage the APU with the pump via a clutch and gearbox.

20 seconds into the run, with the speed approaching 230 mph, he will prime the rocket by filling the fuel lines and pump with oxidiser and injecting a small quantity of HTP into the rocket. The oxidiser will react with a silver oxide catalyst pack, mounted in front of the main propulsion chamber, to create superheated steam and oxygen.

As the solid rubber fuel begins to char in the 600°C temperature, heat haze and black smoke will issue from the rocket exhaust nozzle. As combustion starts, this will turn into a powerful flame. The rocket is now primed, ready to deliver full power at Andy’s command.

At around 350 mph, 25 seconds into the run, the driver will depress the right-hand trigger on his steering wheel, summoning the full force of the Cosworth engine. As the maximum flow rate of HTP reaches the catalyst vast quantities of oxygen will be produced supporting the combustion of the fuel grain and generating 27,000lbs of thrust, a 3000°C temperature at the nozzle and a 25-foot long plume of flame studded with incandescent shock diamonds.

After 20 seconds of acceleration at up to 2.5G, BLOODHOUND SSC will have reached its maximum design speed of 1050 mph. A mere 100 seconds after setting off, the car will be stationary once again - 10 miles from its starting point!

Control system

Even allowing for his many years experience flying fast jets and driving Land Speed record cars, having to prime and fire the rocket, control the EJ200 and ensure that BLOODHOUND SSC is both on course and stable will tax Andy Green’s concentration to the limit.

To help him and ensure his safety, BLOODHOUND features a complex control system designed by Formula 1 systems specialist Dr John Davis.

Cosworth electronics and custom-written software watch over key vital signs including HTP tank temperatures and pressures, pump pressure, inlet and outlet pressures, valve positions, rocket chamber pressure and the temperature of the outer rocket casing along its length.

In the event of an abnormal reading the control system will automatically shut down the supply of oxidiser, thereby extinguishing the rocket. Andy will also be able to shut the rocket down manually.

Ends