The BLOODHOUND Hybrid Rocket System

There are four main elements to BLOODHOUND’s propulsion package: the combustion chamber (containing the solid fuel), the liquid oxidiser, its pumping system, and the associated control kit.

There are four main elements to BLOODHOUND’s propulsion package: the combustion chamber (containing the solid fuel), the liquid oxidiser, its pumping system, and the associated control kit.

The BLOODHOUND Project will test fire its hybrid rocket in the first week of October at the Aerohub, Newquay Cornwall Airport.

The firing will take place on Wednesday October 3rd

BLOODHOUND’s engineers will be testing the complete rocket system for the first time, comprising of the Cosworth CA2010 F1 engine, High Test Peroxide tank, custom designed gear box, software and unique Falcon Hybrid Rocket.

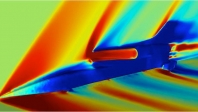

The aerodynamic refinement of the world’s first 1000 mph Car continues. The computational fluid dynamics work at Swansea University is giving us more data on the (now fixed) shape of BLOODHOUND SSC. Fi

Richard Noble talks to Daniel Jubb about how he got interested in rockets

This is part of the coverage of the BLOODHOUND SSC project for the BBC series Bang Goes the Theory

Press Release from the Goodwood Festival of Speed, 1st July 2011

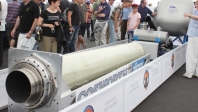

Today, at the world famous Goodwood Festival of Speed, The BLOODHOUND Project displays for the first time the complete rocket propulsion system for their 1000mph Land Speed Racer. Comprising of a custom-designed Falcon hybrid rocket, Cosworth CA2010 F1 engine, pump adapted from the Blue Steel cruise missile and one-tonne capacity HTP oxidiser tank, the system will be soon be tested for the first time in what will be the largest rocket firing in the UK for 20 years.

It was announced today (03.03.11) that The BLOODHOUND Project will undertake the first full test firing of their 122 kN (27,000lbs) prototype hybrid rocket in the UK. Created especially for the BLOODHOUND SSC Land Speed Record car it will be the largest rocket tested in this country for twenty years.

The announcement was made at Cosworth HQ in Northampton. Picture above left to right: Richard Noble, BLOODHOUND SSC Project Director, Mark Chapman BLOODHOUND SSC Chief Engineer, Brian Lecomber, Tim Routsis, CEO Cosworth, Daniel Jubb, BLOODHOUND SSC Falcon rocket

A successful static test of the 45.7cm (18-inch) hybrid was conducted on the 17th of October.

This is the first test of the 111 kN (25,000 lb) thrust chamber, which will be used on BLOODHOUND SSC. Good ignition was achieved and the chamber ran for 10 seconds, combustion was smooth. All hardware was in good condition after the test.

It was a relatively low pressure firing, the chamber was running slightly fuel rich.