The highlight of the past month has been the design conference at the BLOODHOUND Technical Centre in Bristol. The rate of progress in the last few weeks has been dizzying:

BLOODHOUND SSC will use jet fighter tyres for ‘slow’ (250 mph) tests

BLOODHOUND SSC will use jet fighter tyres for ‘slow’ (250 mph) tests

- The wheel profiles have been chosen and we’re completing the detailed wheel design. The wheels will be solid aluminium and the profile of the tread is critical, as it determines who much sideways grip the metal wheels can produce – too much grip and the Car could turn over, too little grip and it will be uncontrollable. After reviewing the wheel designs so far, we’re going for a simple V-shaped keel.

- The wheels for our ‘slow-speed’ (up to 250 mph!) UK runway testing will use jet fighter aircraft tyres. These runway tests will be the first runs of the Car and will be a vital part of the development, before we head out to South Africa for our records attempts. (If you want to come and see the Car being tested in the UK, you need to join our Supporters Club as a Gold Member).

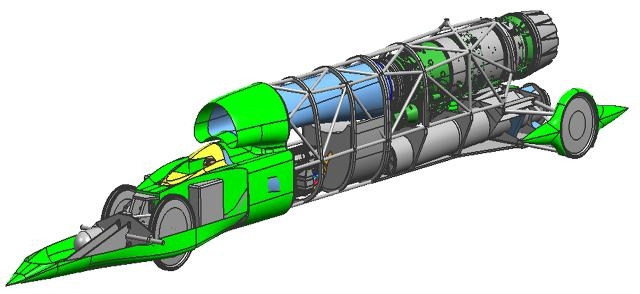

- The control method has been agreed for the ‘winglets’ on the nose and tail of BLOODHOUND. These winglets will trim the aerodynamic loads on the Car (up to 12 tonnes per sq m – which is a lot) if required. We have to keep these huge loads perfectly balanced, without too much down force (which would crush the Car) and definitely without any lift! The latest modelling results say that we’ve found a near-perfect shape and that we won’t need to trim the loads – but at the limits of technology, things never quite work out as you expect, so we’re fitting winglets just in case…

The winglets will be used to trim aerodynamic loads if required

The winglets will be used to trim aerodynamic loads if required

- The installation of the Falcon hybrid rocket has been decided, using a ‘simple’ (in rocket science terms!) clamp at the back end and a quick-release connector at the front. The rocket has to be very securely fixed while it produces the 12 tonnes of thrust that will take the Car from 350 mph to 1000 mph in 20 sec. Then, to set a World Record, we have to replace the rocket pack for a return run within one hour – hence the need for quick-release attachments.

- The maximum load for the brake parachutes has been fixed: 9 tonnes of drag sounds like a lot, but it’s really not much to stop a 5-tonne Car from 1000 mph. The 9 tonnes of extra drag will give us a peak deceleration of minus 3G: much less than this and the Car will go off the end of the track, much more and it will damage the Car (and it won’t be much fun for me either).

- The manufacture of the Car has been detailed (as 300 separate sub-assemblies – no-one said this would be easy). The chassis construction will be carbon fibre for the front half, including the cockpit, and mostly steel and aluminium for the rear fuselage.

Mark Chapman, as Chief Engineer, is doing a fantastic job of leading the team through this process. Mark’s background with Rolls-Royce and Boeing, including 4 years working on the new F-35 joint Strike Fighter, appears to have been perfect preparation for designing the world’s fastest car.

Of course, one tricky problem still remains – finding the rest of the money to pay for the build. We’re still a long way from funding the entire Project, but in the last month we’ve had a surge of interest from major companies, broadcasters, etc. who are seeing the huge commercial potential for the world’s fastest-ever Car. They’ve picked a good time to get involved – the Project is really starting to take off.

We also need to remember that BLOODHOUND is not just about a speed record – it’s about inspiring the next generation of engineers. Our nationwide education programme continues to grow, with students groups fascinated by the design of a 1000 mph Car. We’re delivering to over 3500 UK schools and colleges, and seeing more organisations wanting to get involved in the education programme, which is great – we need all the help we can get. To quote one teacher at a recent education event, ‘Blimey, you’ve got a long way to go to raise the aspirations of some of our students’. Precisely – but if this was easy, we wouldn’t need a 1000 mph Car to do it!

The education message is also going to be very important to our South African audience. Their whole nation is gripped by World Cup fever this month, but after that they’re going to start promoting their next world-class event – BLOODHOUND SSC. I did a video conference with the South African media at the start of May, and the interest is already very high – they can’t wait for us to get started.

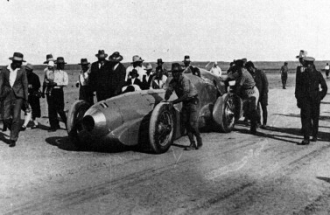

Malcolm Campbell in South Africa, 1929 (photograph courtesy of Castrol)

Malcolm Campbell in South Africa, 1929 (photograph courtesy of Castrol)

There is also a tremendous sense of history about what we’re doing. A couple of weeks ago I spoke to Lloyds Motor Club. I recalled the links between Lloyds and the Land Speed Record: Malcolm Campbell (9 times record holder) worked at Lloyds, as did his equally famous record-breaking son Donald. Of course, Malcolm was also the only person ever to attempt a Land Speed Record in South Africa. In 1929, he ran at Verneuk Pan in the north west of the country, not far from the new BLOODHOUND track at Hakskeen Pan. Campbell just missed the outright record in 1929, so there’s unfinished business for BLOODHOUND to take care of. We’ll be there soon enough.