With the chassis now in manufacture, there are a lot of design details that we need to sort out in the next few months. The most urgent of these is increasing the ‘yaw static margin’. What’s that when it’s at home? In very simple terms, it’s making sure that the fin is big enough to keep the Car pointy-end forwards.

Slightly more technically, we need the aerodynamic centre to be behind the Car’s centre of gravity, to give us a positive yaw static margin. If it’s the other way round, we have a negative yaw static margin and the car is unstable – and as the speed increases, it will become uncontrollable – which is not good. Driving in a straight line in a Car generating 133 000 thp is not going to be easy (have a look at ‘How Hard Can it Be...’ for a few examples), but with a negative yaw static margin (which we currently have) it’s going to be a very short and violent ride.

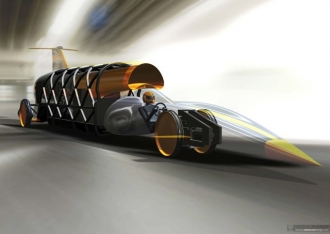

So what can we do? The requirement is to get the aerodynamic centre behind the centre of gravity. We can change the aerodynamics by making the fin bigger and taller (picture above), moving the jet intake (and cockpit canopy) back a little, possibly shortening the nose a little, and so on. At the same time we’re moving the centre of gravity forwards a little by lightening the back of the Car (using less steel and more titanium) and moving the cooling water for the Cosworth F1 engine into the nose. All these small changes will add up to a solution.

Detailed chassis design – work in progress

Detailed chassis design – work in progress

As always, there is an up-side to these changes – we will have more room on the fin for your name to travel at 1000 mph, so put your name on the Fin now!

Why haven’t we fixed this problem before now? Because we couldn’t. This is the last of the ‘big’ airflow problems, but to fix it we first needed to find the body shape that would keep the Car on the ground (‘Config 10’, which took almost 3 years to sort out). Then we needed the position of the centre of gravity – which in turn needs a fully detailed chassis design – which we’re now completing, so this really is the fist chance we’ve had to finalise the yaw stability. This problem is not a show-stopper, just another design challenge in our ‘Engineering Adventure’. We should have a way ahead within the next few weeks – I’ll let you know when we’ve found it.

Daniel Jubb with his Falcon rocket – 75 000 horsepower in a 50 cm tube

Daniel Jubb with his Falcon rocket – 75 000 horsepower in a 50 cm tube

One piece of good news from last month, we’ve just announced that the next batch of rocket tests will be in the UK. If you’ve seen the video of our first full-size rocket test, you already know how impressive this is going to be – the test is planned for this summer on a UK test range, more details to follow soon.

Print your own steering wheel – BLOODHOUND engineer Rachel Trimble hard at work

Print your own steering wheel – BLOODHOUND engineer Rachel Trimble hard at work

Another step forwards with the steering wheel development, with a company called Materialise making 2 mock-ups of the BLOODHOUND steering wheel for us. We are comparing 2 different shapes, one based on Thrust SSC’s aircraft-style yoke and another using the NASA approach of taking a moulding from my hands. This is where Materialise comes in, with a fantastic new technology called ‘additive layer manufacturing’ – literally ‘printing’ 3D copies of our designs. In parallel with assessing the shapes, we need to make sure that the design will be strong enough – step forward Lancaster University engineering students, who will stress the design before we make the final wheel (again using ALM ‘printing’ technology). Another exciting piece of the BLOODHOUND Education Programme in action.

Why is the steering wheel shape so important? At 1000 mph, I will controlling the rocket, airbrakes and brake chutes, plus the safety systems and radio, all from the steering wheel (as shown in our recent Intel animation below) – so it needs to be right. After this optimisation process, it’s also going to look pretty good. As the old saying goes, if it looks right, it probably is.

Clearing the track – the big ones are easy, it’s the small ones that take all the time.

Clearing the track – the big ones are easy, it’s the small ones that take all the time.

The rainy season is in the Northern Cape is nearly over – work on Hakskeen Pan should start again soon. Meanwhile, we got a number of our desert volunteers together at the BLOODHOUND Technical Centre in Bristol last month, to tell them more about the track. We are going out in late May with some of these volunteers, to help with the track clearance and to show the South African media what a fantastic job that the Northern Cape team is doing. Fancy joining us in preparing the world’s first 1000 mph race track? Come along and join us!