I’m a Chartered Engineer with the IMechE and started work on the Bloodhound project in 2010. I had first heard about Bloodhound through a Royal Aeronautical Society lecture by Mark Chapman and decided to try to get involved with the project.

My stress analysis role involves working with Design Engineers and Roland Dennison to ensure the car’s structure is sufficiently strong to cope with the loads anticipated to occur when travelling at 1,000 mph. This involves using both classical “hand” calculations, as well as Finite Element Analysis (FEA), to size a component and help with material selection. Where possible I try to reduce the weight of the structure so the car can go that little bit faster.

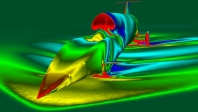

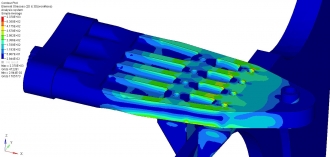

FEA model of the Parachute bracket

FEA model of the Parachute bracket

My second role is as a Research Engineer with Swansea University, where I am working towards my Doctorate in Engineering (EngD). This is similar to a PhD, but is very focused on directly influencing industry via research. I specialize in materials characterization projects, where I test materials that Bloodhound has to use in unique ways. My early projects included identifying whether or not Bloodhound’s steering wheel could be 3D printed out of titanium, as well as optimising the cure profile of an adhesive used on the lower chassis. This latter project increased the maximum service temperature of the adhesive by 20 °C to 80 °C.

My erosion rig, with a Laser Doppler Velocimeter system used to verify particle speeds

My erosion rig, with a Laser Doppler Velocimeter system used to verify particle speedsMost recently I have built my own high speed erosion test rig, so that I can find the best materials to use as Bloodhound’s “skin”.

This is ongoing research and you can find out more on my twitter account, @ChrisHannon_Eng.

In my spare time I volunteer as part of Swansea University’s Formula Student team, where I help out with structural analysis, material selection and parts of the vehicle build. Whenever possible I try to pass on my experience to the next generation of engineers, so that they are as prepared as possible to start their first job in industry.