The inside of any team of persons is an always-interesting and occasionally brutish place to be. I have all the psychological qualifications of a retarded gerbil – but the University of Life long ago taught me there are two main kinds of team: Aggressive and Competitive.

Or so I thought.

Your Aggressive team – one forged for pugnacious purposes, usually military – is paradoxically by far the most comfortable to be in. Quite simply the more dangerous the purpose, the closer the team – providing they are picked carefully. The British military, who get a very great many things wrong in the course of maintaining their grand tradition of political interference leading to high-level bickering, have got this particular aspect resoundingly right. When it comes to serious front-line teams, SAS platoons or RAF squadrons, all the sardines definitely come out of the same tin.

Civilian aerobatic teams also come under the heading of Aggressive. In my early years I flew in a team where one guy was just too bloody aggressive – and it was quite astounding how he only had to walk into a hangar for the Gestalt blood-pressure to rise. When I ran my own team I most shamelessly followed the precepts of the RAF. Any aspirant obviously had to fly very well – but he also had to fit well. If the flying needed polishing we could probably do that. If the fit didn’t feel right – forget it. Fly you like an angel, you still weren’t gonna get on my team.

Then there’s the competitive teams. The people who gravitate to these also tend to have come from the same tin on a supermarket shelf – but in this case the sardines have remarkably shark-like notions. Prime examples are certain big-company sales teams who award their alpha males and females huge rewards for emerging head of the pack. This most understandably pisses off the rest of the sardines, however much they might clap during the awards dinner, and is crass to the extent that wise investors in such companies watch quietly and then equally quietly pull out, uninterested in throwing good money after bad management.

But, I have recently discovered, there is a third kind of team.

One whose members have definitely not all come out of the same tin. Indeed, a team of rugged individualists of widely varying skills, backgrounds, haircuts, appearances, interests and ages – disparities which a body from my neck of the woods would instantly expect to lead to disarray. Especially when, in the nature of the beast, it is a daily occurrence that one member may have a bright idea and another member challenge it. Doomed, you might think this group would be.

Meet the BLOODHOUND team.

Who are not doomed. And who have their own alchemy which frequently makes me blink in astonishment. Okay, I have never before been exposed to a top-class engineering design team. Maybe they are all like this…

But I kinda doubt it. This team is something else.

And it needs to be. Because it is also, right now, a team under very great pressure indeed.

The reason for this is that a certain deadline is becoming close. Indeed, it is rushing up like the Simplon Express, hooting its horn.

In any engineering project you obviously start off with the bits you have to get right. In BLOODHOUND you have to get everything right eventually, of course – but the first thing is the aerodynamics, ‘cos if you haven’t got those right you might as well take up fishing. So you mull, fiddle, experiment, muse, and head off into alleyways which sometimes turn out to be blind, although you won’t know that until you’ve stuck your swede around the corner and tried it. Bearing in mind of course that nobody has ever tried this particular it before, going highly supersonic with a wheeled vehicle. The more outlandish the project, obviously the longer this process takes. In all major ‘breakthrough’ projects – Concorde, Eurofighter, Space Shuttle, BLOODHOUND – there is inevitably a tendency for this phase to become a tad elasticated. Give it a decade and you’ll probably have the perfect design on paper – but you won’t have built anything.

So there does have to come a time when someone chops down a hand and says: “Enough! We’ve now got the aerodynamic solution confirmed, so now we go on to build round it. Period. Got that? Period”.

Er, well, yes. Except that for one thing I used the wrong term when I said ‘build round it’. What I should have said was build inside it, because if you’ve got the aeros sorted out then the outside shape has, ipso facto, at that moment become sacrosanct. So everything you need to cram inside it thereafter must be just that – crammed inside it. And no arguments.

(Except one obvious one, which I know to be hopeless but you have to keep plugging away – to wit, that if you had Lecomber driving it you’d have at least a foot more fuselage space because Lecomber is at least a foot shorter than Green. Oh all right, all right – I know I’m wasting my time…)

The other, and much more important, thing is that whenever you draw a design line in the sand someone is always going to stick up their hand and say “Hey, Boss, we’re not quite ready here yet”.

This can create a certain amount of high drama.

Everyone on the BLOODHOUND team wants to chop the karate hand down at the end of September. Two weeks away. At the front end of that wants is Richard Noble, who has two big feet. One of them in the design camp, and the other in the commercial world. His commercial foot tells him BLOODHOUND must keep the loud pedal down to maintain inertia in order to keep up interest and sponsor money – yes, especially sponsor money, and especially sponsor money to expand the design team for the next phase – coming in. His design foot says much the same thing, and he is avid to see two things happen by the end of the month – the aerodynamic solution, and also the first ‘wet’ – fully-fuelled – test-firing of the full-size Falcon rocket 12,000 miles away in Dan Jubb’s Mojave test facility.

This does not, let us be frank about it, especially make for peace and quiet.

Indeed, on the face of it, it could look like a recipe for conflict. On the one hand a design team observing British Summer Time – and on the other an individual operating on RNT – Richard Noble Time. Which tends to run a bit faster.

Well, I don’t think there will be conflict. Er, well, not much, anyway. Everyone is aimed at the same target, and if the Design Team really aren’t quite ready for Aero Solution on 30 Sept they are most certainly capable of folding their arms and saying so, and there will then ensue a brief squabble with a cloud of feathers. Following which the date might slide back by a fortnight or so, but not much more. That is the worst-case scenario. That’s as I see it looking in from the outside. It is quite probable that this observation will go down like a concrete parachute with everybody concerned, but it is the fact.

Period.

Nobody ever said that this adventure would be easy.

And – please excuse me while I borrow a vulgar expression from our American colonial cousins – nobody ever said that certain persons involved would not at some time find certain sensitive parts of their anatomy uncomfortably positioned in a vice not of their making.

Well, meet Ben Evans.

To tell the story of Ben Evans I must go back in time a smidgeon or two.

BLOODHOUND’s Chief Aerodynamicist is Ron Ayers, a courtly gentleman of vast knowledge and experience. Ron – who should certainly be Sir Ron Ayers were there any justice in this sovereign nation of ours – originates and oversees the aerodynamic developments of BLOODHOUND.

Then this Ben Evans knocks them down. I will explain in a moment.

Ron Ayers began his engineering career in 1950. In 1950 the two people who would eventually marry and create a baby called Ben were not yet born themselves. In 1981, when Ben Evans came into the world, Ron Ayers had been working in aerodynamics and engineering for 31 years.

Now they are on the same team. The baby Ben Evans is now Doctor Ben Evans, his doctorate being in the esoteric world of Computational Fluid Dynamics. Designs emanating from Ron Ayers go through the BLOODHOUND design office at UWE in Bristol, then on to Ben for CFD analysis at Swansea University.

Where Ben, when appropriate, knocks them down.

As I write this I can palpably feel the team’s hackles rising at the term ‘knocks them down’ – said hackles being led by Ben Evans himself, seconded by Engineering Director John Piper, watched amusedly by Ron Ayers, and causing Richard Noble’s expression to shift into a pattern which puts me in mind of certain tropical cumulo-nimbus clouds I have tangled with, complete with reddish sunset tinge.

But I stick to my guns. Ben’s task, to a not inconsiderable extent, is to knock down ideas.

Except that in BLOODHOUND life it doesn’t work like that. It doesn’t work like that at all.

Where the aerodynamic buck stops

This young Dr Ben is, if you like, where the buck stops in the aerodynamic design chain. Designs, and modifications of designs, come from the Design Office in the form of CAD files – Computer Aided Design – which Ben then subjects to a programme called CADFIX and finally analyses using a thing called a CFD Mesh.

This CFD analysis is the teller of truths. Ron Ayers made use of the – well, not exactly nascent, but then less well developed – technology of CFD back in the ‘nineties when he was designing Thrust SSC. Given a few um’s and er’s CFD worked pretty well back then – well, only just, to tell the truth, since Thrust SSC was only a few thou removed from a death-trap – but in the intervening years the science has come on apace. So much so that this time around the BLOODHOUND team rely on CFD totally. The alternative might be a supersonic wind-tunnel, of which there are a few about on the planet but all dedicated to machines of the air. Of supersonic wind tunnels which can also pass simulated ground under a car model at 1,000 mph there are exactly none on this planet or any other. So CFD is king.

And the first person to see and to analyse BLOODHOUND CFD results is Doctor of Computational Fluid Dynamics Ben Evans.

Whatever the news – good, bad or indifferent – Ben sees it before anyone else. And so the now 28 year-old Dr Ben Evans has to stand up in front of the whole design team and deliver such cheery news as the XYZ configuration of BLOODHOUND has five tonnes of aerodynamic uplift at the back end at supersonic speeds. Should make him a real popular guy, yes…?

Well, in fact…. yes.

Discovering what NOT to do

The BLOODHOUND team do not bat an eyelid at such news. Well – not much, anyway. Nobody even thinks about saying “Are you sure? Have you re-checked?” Dr Ben Evans has re-checked and if he wasn’t sure he wouldn’t be standing there.

And this is where the BLOODHOUND team differs from any other crew I have ever experienced. To them, working in this utterly outlandish supersonic dragon territory where no person has ever travelled before – where to use Ron Ayer’s words there is no ‘prior art’ – all trustworthy inputs are progress. And what might appear to be progress backwards – such as announcing the small detail of fives tonnes of rear uplift – is still progress, because discovering what not to do is a most vital step towards discovering what to do. There is no such thing as a messenger of doom. Just progress. Period.

So meet Dr Ben Evans. On the face of him a quiet, gentle guy with a slight Welsh accent and a charming smile – and behind that a polymath with an IQ up in the telephone numbers. And an iron determination.

At the age of 15 Ben did two weeks work experience at a flying club – and decided that he wanted to be a pilot. Ultimately, an airline pilot. Flying lessons are not, however, cheap, and the gap between ‘wanting’ and ‘affording’ was a chasm of most daunting proportions. So for the next two-and-a-half years Ben did two paper rounds every day plus a Saturday job – and spent every red cent on learning to fly. He gained his Private Pilot’s Licence at the age of 17 – which, I can tell you as an ex-flying instructor, is a most remarkable achievement for a self-funded schoolboy doing two paper rounds and a Saturday job.

It is not easy to become an airline pilot. But by the end of his schooling Ben would have walked it. Any person in their late teens with his bunch of A levels and a self-paid flying licence would have clanged the bells of any airline who were recruiting neophytes at the time – which several were.

Ben, however, went to Cambridge University for four years, there to acquire a degree in Aerospace and Aerothermal engineering. No hindrance to a subsequent airline career – airlines actually like their pilots to be egg-headed rather than square-jawed if they can get them – but during which time Ben, wafting around in powerless aircraft in the University gliding club, slowly came to the conclusion that airline flying wasn’t for him. That he would get bored and stale with it, and end up not enjoying it.

This was a most intelligent decision. Modern airlines are places where you get up at three in the morning, tie your tie on straight, and then go operate computers with an aircraft tagging along behind. Not an entirely fair assessment, of course – but it sure ain’t no life for someone who enjoys flying. In odd moments I wonder where Ben might have gone if he’d taken up aerobatics…

Anyway, he didn’t. What he did after Cambridge was to return to his home town, Swansea, and go to Swansea University there to take a PHD in this Computational Fluid Dynamics business. And having won his Doctorate, there to join the University staff as a Senior Research Assistant. And that, of course, is where he encountered BLOODHOUND. Swansea Uni boasts one of the finest CFD research facilities in the UK, and they were heavily involved with the design of ThrustSSC back in the ‘nineties. So when Richard Noble went to Swansea to talk about BLOODHOUND, they said: “Ah, we have just the young man for you….” And so Ben was seconded to run the BLOODHOUND research project.

So how does CFD actually work?

Ben states that it’s an application of the finite element method of computational modelling to the governing equations of molecular gas dynamics, so as to predict macroscopic flow behaviour in terms of the underlying molecular kinetics. To achieve a 3D finite element solution it is necessary to discretise the solution domain into a finite number of small cells / elements forming a mesh or grid, and to then apply a suitable algorithm to values stored at the intersections of the mesh to solve the governing equations.

1,820,459 Big Macs

I am now looking at Ben with my jaw hanging open. I had no idea that one of his further qualifications was to speak archaic Latin with a dash of Esperanto thrown in. I can only confess that I do not have the remotest idea what he’s talking about. I think it means that you take the CAD design and surround it with 65,000,000 virtual tetrahendons – not an exageration, 65 million tetrahendons – creating tiny ones near the surface of the vehicle and bigger ones as you go further out. You then get the computer to analyse the airflow in each tetrahendon and establish the results into a useful format showing pressure, shockwave, lift, drag, downforce, etc at various speeds.

Er, well, maybe.

If I was allowed anywhere near a computer programme like that the result would probably be an inadvertent electronic order for 1,820,459 Big Macs, which might just be a slight embarrasment, not to mention a tad niffy and not all that good for you.

The point, however, is that each CFD analysis on a full BLOODHOUND re-configuration takes 24 to 36 hours of run-time on a super-computer half the size of my house. Ben now has access to enough computer-power to run six configurations at any one time – which must make even his brain ache – but even so it does mean that time must pass. Config 9 – jet over rocket with variations of rear wheel layouts with delta ‘wings’ about their persons – is looking good. But you still have to sit there while the computer chews its way through 65 million partial differential equations, and then analyse the results.

With two weeks to go before confirming the aerodynamics solution. It says here.

Which is how Ben Evans, along with most of the design team, come to find certain bodily parts dangling in a vice. Everybody wants the Karate hand to chop. Everybody recognises it is essential. The question is – just when?

A tense time then, right now.

But nobody ever said this adventure was going to be easy.

Postscript

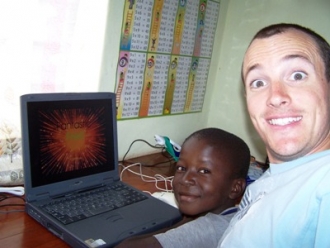

Not the most flattering picture of Dr Ben Evans - but note the kid and the computer behind him. Ben spent his holiday this year in an orphanage in Zambia setting up a computer room and teaching the kids how to use it ...

Not the most flattering picture of Dr Ben Evans - but note the kid and the computer behind him. Ben spent his holiday this year in an orphanage in Zambia setting up a computer room and teaching the kids how to use it ...

Ben, unlike my badself, is a very devout Christian. He states quite plainly, without the slightest hint of evangalism, that he tries to follow the example of Jesus. And of course, being Ben Evans, this is not just hollow words. Oh, no. For some time now he has been sending a percentage of his not over-generous University pay to an AIDS orphanage in Northern Zambia, who look after – well, AIDS orphans, between the ages of 5 and 18. This last Easter, Ben took his two-week holiday to go out to this orphanage – not exactly the resort of choice for the smart set – to make sure they were using the money for something more constructive than stocking-up on the local hooch or sweetening the local politicians. Turns out they weren’t. Oh, and he also took along five computers he’d gained from a British charity, set them up and got them running in a newly-created computer-room at the orphanage, and then spent the rest of his fortnight teaching 44 kids how to use them.

I may not – perhaps sadly – share Ben’s beliefs. But if I was strapping into a 1,000 mph car, my tension would be at least somewhat calmed by the knowledge that Dr Ben Evans had been the aerodynamic backstop.