Work has been continuing apace at the BLOODHOUND Technical Centre over the last month, where the main focus for the Team has been preparing the lower chassis and fuel tanks for a jet fuel systems test in mid-December. This test will cut across multiple systems, giving the engineers an opportunity to check all the parts fit together, and make sure there are no leaks and that the pumps can deliver Jet A into the EJ200 jet engine under incredible acceleration and deceleration loads.

Work has been continuing apace at the BLOODHOUND Technical Centre over the last month, where the main focus for the Team has been preparing the lower chassis and fuel tanks for a jet fuel systems test in mid-December. This test will cut across multiple systems, giving the engineers an opportunity to check all the parts fit together, and make sure there are no leaks and that the pumps can deliver Jet A into the EJ200 jet engine under incredible acceleration and deceleration loads.

Jet fuel test preparations

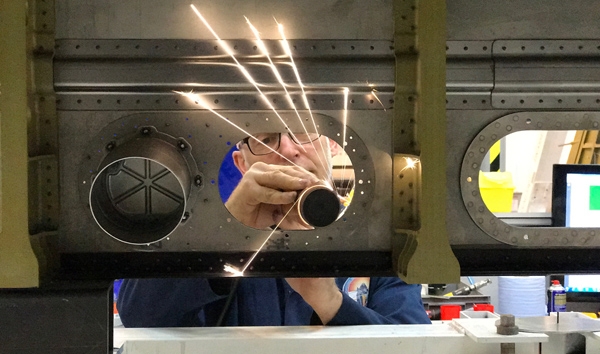

One key task was to prepare the main and auxiliary jet fuel tanks and install them in the lower chassis. Our Team was supported in this by product sponsor Advanced Fuel Systems, who helped them install the internal fuel bladders, foam, pumps and internal pipework.

This stage of the project involved the Team working with their arms buried deep inside the fuel tanks, which was a real challenge, but it has been a great exercise to assemble this section of the Car and see how everything comes together.

Another task was to prepare the lower chassis. A steel framework was fabricated and installed at both ends of the chassis to support it during the fuel systems test, because the chassis will be lifted to around 60 degrees off the ground to simulate the angle the jet fuel will be pushed to as the Car accelerates and decelerates while doing the runs in the desert.

Another task was to prepare the lower chassis. A steel framework was fabricated and installed at both ends of the chassis to support it during the fuel systems test, because the chassis will be lifted to around 60 degrees off the ground to simulate the angle the jet fuel will be pushed to as the Car accelerates and decelerates while doing the runs in the desert.

During the tests, the rig will be tipped one way to simulate acceleration and then the other to simulate deceleration. The pumps, flaps (which are like cat flaps) and controls will be checked during both to ensure that our engineers fully understand everything about how they work before we run the Car during real operating conditions on Hakskeen Pan in South Africa next year.

The Team has made custom electrical boxes to hold the electronics needed to run the jet fuel systems test. During the test we will also be running much of the Car’s avionic system that controls the EJ200 jet engine, which in turn will control the pumps in the tanks.

Also this month

We’ve also been working on the upper chassis as well this month, making some of the last additions before it goes for its paint job during December – these included:

We’ve also been working on the upper chassis as well this month, making some of the last additions before it goes for its paint job during December – these included:

- the fin shear plate doubler was added to increase the strength of the surrounding chassis

- work continued on the AMAD exhaust hatches (the AMAD starts the jet engine and then generates AC, DC and hydraulic power for the Car).

Our Team is growing ahead of the planned runs in South Africa next year and the Design Office is busy working on the remaining parts for the Car.

Coming up

We have a busy month ahead, with the challenge of getting the Jet A fuel tanks signed off, the upper chassis being sent off for painting, and more and more parts being released for manufacture. We will make the most of every working day in December ahead of taking a well-earned break for Christmas!