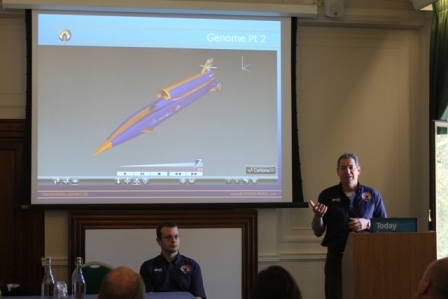

3D imagery captures 30 man-years of design effort

The BLOODHOUND Project publishes today the full design drawings for its iconic jet and rocket-powered World Land Speed Record contender, BLOODHOUND SSC, at the London headquarters of sponsor the Institution of Mechanical Engineers.

The BLOODHOUND Project is an international education initiative focussed around a 1,000 mph World Land Speed Record attempt. The core aim is to inspire young people to pursue careers in Science, Technology, Engineering and Mathematics (STEM subjects) by showcasing these subjects in the most exciting way possible.

Cutting-edge high technology projects of this calibre are usually shrouded in secrecy, but a key aspect of the BLOODHOUND mission is the aim of sharing the adventure – and data – with the biggest audience possible. Consequently, the design drawings will be distributed to over 4,500 schools and colleges across the UK, where they can be accessed by over 1.5m students, and to our extended team of fans and enthusiasts following the Project in the 207 countries around the world.

John Wood, President of the Institution of Mechanical Engineers said: “It’s unprecedented to release detailed design data from a project like this, yet it’s part of the unique appeal and importance of BLOODHOUND to demonstrate how sophisticated engineering works. “This world class project demonstrates the remarkable creative and technical skills already in the UK, and we hope it will inspire a whole new generation.”

Mark Chapman, BLOODHOUND Chief Engineer, added, “If you had a spare jet, rocket and F1 engine, you could, in theory, use these drawings to build your own BLOODHOUND at home. Much as we enjoy a good race, we don’t recommend it. Things get pretty hairy when you travel faster than a bullet!”

The downloadable 3D design drawings, that make up the car’s genetics, are the result of an incredible 30 man-years of cutting-edge research and world-beating design work. Comprised of 4,000 individually-designed components, you can deconstruct the CAD model layer by layer, rotate on all axes and zoom in and out, using professional engineering software from Siemens. Visit the BLOODHOUND website for links to download.

The 3D design drawings allow viewers to explore the remarkable engineering that allows BLOODHOUND SSC to accelerate from 0 -1050 mph and back in just 100 seconds and safely handle the phenomenal forces and loads acting upon it: the 47,000 lbs thrust (equivalent to 133,000 thp) generated by its jet and rocket engines; 30 tonne suspension loadings; air pressures on the bodywork of up to 10 tonnes per square metre; the air brakes each exert 2.2 tonnes as they open; solid aluminium wheels alone weigh 90 kg each and will be spinning at 10,200 rpm, generating 50,000 radial g at the rim.

Unlike more traditional forms of motor sport, like Formula 1, there is no competitive risk in sharing secrets. World Land Speed Record breaking is bound by a few rules, namely: the car must be continuously controlled by a driver, run on at least four wheels and make two passes through the measured mile within one hour. This means that land speed record challengers enjoy almost total freedom when designing their car and it explains why, in 1997, Thrust SSC, a four-wheel twin jet-engined car, was able to race Craig Breedlove’s single-engined, five-wheeled Spirit of America. Physics levels the playing field, not a book of regulations.

The 3D design drawings will be used extensively in the BLOODHOUND Education Programme, which produces curriculum-ready resource materials for all levels of education. Currently 4,081 primary and secondary schools, 246 further education colleges and 42 universities, encompassing 1.5 million students, are now exposed to real-world case studies based on the jet- and rocket-powered Car, helping to bring their Science, Technology, Engineering and Maths (STEM) lessons vibrantly to life. Schoolchildren across the country are already building their own pyrotechnic rocket cars, go-karts and even a life-size replica of the BLOODHOUND cockpit complete with seat, steering yoke and dials. So, who knows what imaginative projects will be inspired by the release of these design drawings.

After 36 months of detailed design work, refined versions of these newly released design drawings have been issued to key BLOODHOUND suppliers including Hampson Industries Plc, who will shortly commence cutting the first steel and aluminium to fabricate the rear chassis. Meanwhile, Cosworth Ltd are close to completing preparation of their Formula 1 racing engine and software package ready for the largest rocket test the UK has seen in 20 years – due to take place this Summer.

Ends