It's that Nick Chapman again - our webmaster: Richard the last blog was in May, can we have another please !

I am sorry about my failure to communicate, but the workload here is massive and anything that generates money for the team takes precedence. We are a very small company to be taking on such a massive programme and the personal workload is very high – but I am glad to say we are getting there.

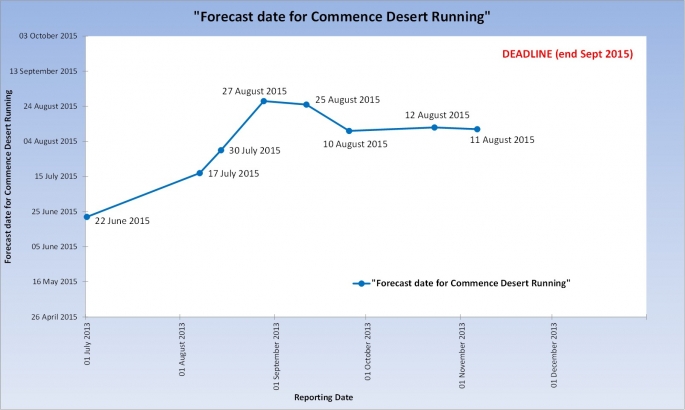

As you know the BMT-HiQ Sigma team are very generously doing our planning and at a meeting last week Russell Tarver and Colin Higginson produced the latest copy of the Slip Chart. The planning is updated at least once a fortnight and this huge plan calculates the end date – which in this case is the first day on the Hakskeenpan. It's very complex and very thorough. Every forward activity will have an effect on the end date. Mark has been able to increase the design team numbers and with this extra resource we have been able to hold the end date at August 11 2015. From the chart you’ll see that the date has varied with the developing plan and has been as late as August 27th – which was where we were on September 1st this year. You can see now that the end date has stabilised and now we have to work hard to bring the plan to the left – that’s planning speak for finishing earlier!

It's important to understand that completion of a car build on this scale is very tough – as the car comes together in the last final months there is a myriad of last minute things that need doing – and of course things do go wrong and the plan takes no account of rework.

Life for everyone in Bloodhound has become something of a blur. Ask anyone what they were doing two days ago and they’ll have difficulty – the pace is relentless, as one day merges into the next. At my end it’s a blur of invoices, contracts, a few shocks, many new people starting, a few people moving on. The project has gone on for much longer than we originally planned, many have been on the programme for 5 years or more and it now accounts for a big part of everyone’s working life. It’s been a huge personal commitment from everyone - and the company has had to change from being a research company to being a production company driven by its deadlines and its much increased financial needs. It has become much more like a normal company in that respect. I try to get to Avonmouth for at least two days a week, but often that is just not possible – I have to meet sponsors and our financial needs and that can take you anywhere – and today I am writing this in Arizona doing a long promised four day US lecture tour for one of our earliest sponsors SGS Tool who have been with us since 2008 supplying specialist carbide rotary cutting tools for our suppliers and our machine shop.

But the huge buzz is of course to be found in Avonmouth where the car is coming together: it’s now beginning to look like our car and many of the components we have talked and speculated about for so long are now in place. Even that bone of contention the static margin has turned out much better than anyone expected, so stability is no longer the issue it once was. But by the time I get back to Avonmouth the car will be in pieces again as Chris Dee and team start to build up the upper chassis – just a small matter of formers, titanium stringers and skin and 11,500 rivets! The fin comes next and that’s a huge job. Since we are going faster than any aircraft in the thick air at 3000ft, the fin is going to be the fastest fin of all time at this altitude! The parts are really beautiful; the suppliers are giving their all and despite all the battles and anguish needed to keep the company going, just the occasional opportunity to see the car in build gives you the next fix to enable you to draw breathe for a few minutes and then dive back into the morass of accounts, contracts and the endless battle to get Bloodhound completed.

As I said, we are too small a company to take on a massive programme like this – we are building the equivalent of a prototype jet fighter together with its advanced jet engine and the prototype rocket engine. Governments spend billions employing hundreds to do this work- and we are only 61 – and that includes the education team. We are funded by sponsorship, and no self respecting aerospace company would try what we are doing on such risky financing. But we are getting there – if you look at it objectively as Mark Chapman did the other day, all the technical issues now have solutions – we can do this. Its taken 6 years and around 120 man years of work, and of course it’s all innovative. Almost everything we do is innovative because we have to; often we don’t have the time or money to do things conventionally. Ask Conor La Grue about URT’s resin infusion manufacture of the EJ200 intake, ask Jo Finch about the development of the reciprocal community BLAST website. It's exactly as Lord Kelvin once said: We don’t have the money ; therefore we have to think.

We live in our World here – most people work six or seven days a week and we keep the car build developing according to the master plan. Actually that’s not quite true, Chris Dee and the Assembly team are hell's bent on beating the plan. That puts huge pressure on Conor who has to deliver the parts and he tends to get highly frustrated with the design engineers who of course have to produce and sign off the drawings before he can commit them to manufacture. The pace has to be set by the Assembly Team – because that is the net sum of what we are doing. Regardless of the internal machinations, the car is coming together really well. People outside the team are amazed at what’s happening - they can see it's really progressing and there is huge interest, excitement and anticipation. For us, we are the long distance runners in the middle of the toughest marathon I’ve ever experienced. There is no time for excitement and anticipation – let’s get that next invoice paid and the next part made.

British Business Secretary Vince Cable meets Ian Glover and Bloodhound SSC

British Business Secretary Vince Cable meets Ian Glover and Bloodhound SSCLast week I found myself giving a presentation on innovation with British Business Secretary Vince Cable. Vince was talking up innovation - I wasn’t so sure. In Britain we need innovation like never before. The conventional doesn’t work any more and we need new ideas, new products, new processes. So take a moment to think about this, how on earth do you innovate in a stable safe country like Britain where all the risk has been surgically removed? I explained in the presentation that you need instability, education, available finance, and a culture that demands the new and demands to take part . That was the mix that Britain had in World War 2 – and look at the innovation – biplanes to jets in 6 years! In the UK today our education is not good and there is almost no venture capital, our media is still predominantly negative and focusses entirely on the soft stuff, with minimal science and engineering. The kids in school only have football and XFactor to look up to; their virtual World of online games and cartoons is depressingly fake. And people are frightened to death of risk. Well here’s news for you – at Bloodhound we embrace risk we live with it day by day –every one of us, we have invested an awful lot of our lives in this project . And it’s very very real!

I finished the presentation and return to my seat. Vince leaned over: That was really very good he said.

I enjoy my meetings with the Royal Bank of Scotland: we meet up every three months or so to review progress. They freely admit that they have never seen anything like Bloodhound – the 600% growth rate, the long forward plan with big blanks for incoming revenue, the dependence on sponsorship public donation and merchandise sales. And yet every month now there is a new surprise, another big deal has emerged – we are now being contacted by companies who want to sponsor. But the deals are getting larger and although the technical risk is much reduced, the financial risk gets tougher as the numbers get larger . And so we push on, October is behind us, the bills have been paid and now we have to focus on December and January –and it’s looking good.

In fact we are in uncharted waters now – the deals are getting larger and more frequent. There is a tremendous buzz about the place, Bloodhound is really on its way. But we can’t enjoy this – there is a huge amount to achieve and we have to keep batting away at that plan. Curiously there is now worry in the conventional motor racing circles. A recent TIME feature explain that the normally bulletproof US NASCAR series is down 38% in revenue and in Formula 1, Red Bull is winning every race which is not good for a sport which depends on challenge, excitement and the unexpected .

Our education team is into big change. We are incredibly grateful to Chris Kirby for holding it all together for so long. It was always going to be a temporary arrangement as Chris could never commit to a long term association or to more than two days a week. He brought tremendous experience and knowledge to the team and he landed the big DFE grant. As the education project grew so did Chris’s concerns and he made it plain that his time was up: Bloodhound Education was on the cusp of becoming very large, very innovative and needs a great deal of time and commitment.

October the 17th was the big day.The day I chaired the Bloodhound Education Team (BET) planning meeting, we would rethink our activity and find ourselves a new director:

OK its all innovation and all change – we have 5,500 UK schools signed ; you are the specialists now- what do you think we should be doing?

Frankly I was very concerned about the meeting – what would happen? Everyone in the BET is very connected focussed and very proud of what has been achieved and very concerned about the way forward.

I needn’t have worried – we started the whole thing from scratch and in a few hours Bloodhound education had changed for ever. The need they saw was to open the education right up, keep the focus on science and engineering but start to bring in self discovery. The new mission statement says it all

Changing Perceptions by inspiring Curiosity and Self Discovery

I was used to rather long complicated BET meetings, but this was different – the innovation and determination was all there. We made the changes in very short order. This is going to deliver big time. The immediate need is to get down to the 240 education days over two years programme that we have promised the Department of Education.

But the BET efforts become ever more important – if you have a look at the October BBC OECD report - you’ll be able to see just what is happening to UK education – the country is now 22nd for literacy and 21st for numeracy, out of the top 24. Back in 2000, the country was a very respectable 8th and 4th. The report goes on to state that England is the only country in the survey where the results are going backwards . The older generation are better educated than the current. Inspiring the school kids and encouraging opportunity is absolutely essential to get us out of this spiral of decline and with 5500 schools now using Bloodhound we must be in a position to make a serious impact. Curiously the US is in a very similar situation.

I am now back in South Africa and there is something very mighty building up here. The huge MTN masts are up and the desert work is now within 10 weeks of completion. There is massive interest developing – Dave Rowley and Wendy Maxwell running Bloodhound education have now reached the 450 schools mark and they are now being joined by the amazing Aloysius Gonzaga, as well as 100 ambassadors. You are going to hear an awful lot about this team as the whole show comes together big time. The word is getting out that Bloodhound is going to be a big event in 2015 and 2016. I am just so glad we found this wonderful desert and the South African people who have given us such a welcome and such support .

Back on the beautiful Alvord desert, the North American Eagle team are making steady progress and Jessi Combs has just passed 440mph using afterburner. The car seems to be stable enough so now they can pile on the power and start making solid progress. After all 600mph is only 150 mph ahead! I remember when we first did that with Thrust 2 way back in 1981. It had been a huge struggle on the Bonneville salt flats and I was worried about adding power to an unstable car which had already gone seriously out of line at 175 and 300mph. On one run I just got fed up with our inability to deliver and just banged in the afterburner. The car shot ahead straight as an arrow to 500mph and then we lost battery connection, fuel pressure and engine power. But we had achieved something, we were the fastest ever British car and we could now look ahead to greater things. But not immediately because it rained that night and we had to pack up and go home!!! Oh yes - and win a battle for our insurance claim – but that’s another story !!

So Jessi is on her way and you need to follow on the North American Eagle website.

But hang on, there is more excitement in all this! On October 4th we celebrated holding the World Land Speed Record for 30 years and on the 15th, the ThrustSSC supersonic record day, for 16 years – the longest any land speed record has ever stood. The BBC even screened the 1983 documentary ‘For Britain and the Hell of it’ (which has been digitally remastered and now available on DVD here) which was a huge credit to the team. But to do the real celebrating, we got Thrust 2 and ThrustSSC team members together at Coventry Transport Museum for a happy lunch and then shared the afternoon with the Bloodhound 1K Gold members to run the Thrust 2 documentary followed by Thrust2 team member John Norris’ private video of the Thrust2 story. No one had seen John’s video for 30 years and it worked really well following the official BBC documentary. But there is much more to come, the Coventry Transport Museum has just won an £8m grant to restructure the whole museum with Thrust2 and ThrustSSC out in front. On top of that, Director Gary Hall announced a further grant of £500,000 for the Thrust cars display. He made the point that he will keep space for Bloodhound, I told him he had better start saving !!!

We have just completed a week's exhibition in Parliament – trying to get the MPs to understand what Bloodhound is about and to realise the importance of getting their constituency schools and manufacturers involved. It seems that previous parliamentary exhibitions tend to be passive and consist of banners and handouts. By contrast of course, Bloodhound was shared with our sponsors IMechE and was highly active with our ambassadors and BET team taking part . The big draw was the Bloodhound Driving Experience – with all the MPs challenging for fastest time – and of course setting out to to beat the Chancellor George Osborne’s score of 1007.30 mph . A highly competitive challenger was Science Minister David Willetts with a very creditable 1013.00 mph. But the fastest parliamentary record was 1024.80 mph by MP Jack Lopresti. That will take some beating by our parliamentary friends !

Bloodhound and Richard Noble at the House of Commons

Bloodhound and Richard Noble at the House of CommonsSo back to the project and the deals – there are currently five deals in process now, and only 20 months before operations on the Hakskeenpan and we have a long way to go still. But as Mark makes the point – the technical issues have solutions – and that is the news we have been waiting for ... for 6 very very hard years !

Richard Noble, November 2013