Well, we have made it through August and the last months have been enormously productive as the whole Bloodhound programme matures and comes together. I am writing this from the cruise ship P&O Arcadia in Scotland where I lecture twice a year. This is a brilliant arrangement as I get a few days of good food, plenty of sleep, and an opportunity to study and to rethink Bloodhound. The project is moving so fast now and has a culture of its own, that time to think strategy is very hard to come by.

In Bristol, Mark and the design team are pushing on hard with detail design and weight reduction; there had been conservatism in earlier work which has resulted in the car becoming heavier than planned. Weight is a real problem with these land speed record cars – too much weight slows up the acceleration which means you need a longer track or more power (and more power means more fuel which means more weight) – and even worse it makes stopping these low drag heavy bullets of cars much more difficult. As Andy is fond of saying ‘Accelerating is optional, stopping is mandatory‘.

So weight control is vital and the time to catch it is in design, not later when the car runs off the end of the track!

We regularly crosscheck all this with Ron Ayers' huge performance plan which takes into account every conceivable variable. It's crucially important to catch any divergence right now.

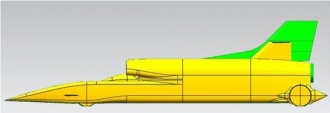

The project has had to change considerably – it's taken 30 man years to get the research through and a steady and long haul by the engineers to get the design to a safe point where we can do it. During the research phase there were no obvious answers and the team has had to plough on steadily working its way through endless design iterations and then perfecting the final layout. The fin is the last aerodynamic fix – you’ll see that the fin has increased substantially in size, but because its chord (width) increased for the same thickness, its overall drag is less than the original. The organisation has had to change from being a research organisation to one which is punching out production drawings now we are into build. But slowly, because we need more in the design team.

The project has had to change considerably – it's taken 30 man years to get the research through and a steady and long haul by the engineers to get the design to a safe point where we can do it. During the research phase there were no obvious answers and the team has had to plough on steadily working its way through endless design iterations and then perfecting the final layout. The fin is the last aerodynamic fix – you’ll see that the fin has increased substantially in size, but because its chord (width) increased for the same thickness, its overall drag is less than the original. The organisation has had to change from being a research organisation to one which is punching out production drawings now we are into build. But slowly, because we need more in the design team.

It is important to understand that we are building the equivalent of a high performance jet fighter (in fact Bloodhound will out accelerate any jet fighter!) and carrying out this whole professional operation on a very small budget funded by sponsorship and public support. Tight planning is essential because our cost base has to double and delays can kill the entire project. As an example, a one day delay on delivery of a critical path item will extend the project by a further day and cost £12,000 which has to be found from somewhere. This then runs us into problems with sponsored manufactured parts – so often the generous sponsor tends to understandably give production priority to other work which pays, and the Bloodhound part is delayed . We can no longer accept that and it becomes essential that we have a very tight supply chain. In fact it is often preferable to pay for the part, but that of course then moves the problem to the funding team! Of course there never are problems in this organisation – just opportunities!

So it is Conor La Grue’s job to run the supply chain and ensure the timely delivery of all the manufactured and off the shelf parts. And of course to fit in with The Plan. Dan Johns runs The Plan and last month we turned the original plan upside down. The original plan was very detailed but it had one serious fault – it was a traditional top down plan. This meant that it was created by the engineers anticipating manufacturing and assembly times. The concern was that it didn’t take proper account of the Assembly Team's sequencing and there was a real danger that parts might not arrive when they were needed. If delivery of a key part were to be delayed by say 4 days, then the project cost would escalate by £48,000. Of course it's never as simple as that because the Assembly Team would try and work round the missing part – but working around is always expensive and often means that at a later stage, assembly has to go backwards because the workaround –well, just hasnt worked around!

So the plan starts with Assembly and that is Chris Dee’s operation. After a few days of hard graft, the Assembly Plan comes together. This then impacts on Conor because Chris has then set the dates when he needs component deliveries. Conor has to source the component and plan for its manufacture – which then of course impacts on Mark and design team who have to sequence the detail design programme so that they can deliver the drawings in time for manufacture. So the whole operation is driven by Chris Dee and the Assembly team.

And Mark needs more design engineers and more design resource – so of course the whole operation impacts on the funding team! Can we achieve all this in a period of dire financial stagflation? Can we expand the engineering team fast enough?

The whole operation has to be very smooth and well managed and just to make it more interesting, we are going to put the plan up on the web and link all the critical milestones into the Rolex clock on the home page. This might look like a massive self flagellation exercise, but everyone has to understand the importance of those milestones – they have to be met! And when they are met we’ll have Bloodhound on its wheels by the end of December 2012. We are all committed to 18 months of sheer hell while we get all this together – it's a period none of us are ever likely to forget, and I am making the most of my few days on the Arcadia!

Dave Rowley has just come back from his education trip to South Africa . He reports that exactly 5558 miles South of Bristol, the Northern Cape Government are making tremendous progress on the desert and the day he was on Hakskeen Pan there were 100 people working on stone removal . We now have to get a big push on the desert to try and get as many of the surface stones removed before the rains come. If we can achieve this by the end of 2011, then the desert will get 18 months to consolidate before Bloodhound arrives. It is important to understand that the rain and flooding does not seem to shift the stones – if you go to nearby Verneuk Pan, Sir Malcolm Campbell’s 1929 track is clearly visible and much of it stone free despite 80 years of annual flooding.

Dave reports that the Northern Cape Government is making serious progress with education in the province (as big as Germany) linking much of it to the Bloodhound project. He reports on huge levels of interest and awareness as the programme begins to develop. Andy Green is going there for a lecture tour later this year and we are now being contacted by would be local sponsors.

Back in UK, Gary May is planning up the next stages of the education programme which is to focus on in depth presentation in each of the 9 UK regions – making sure that the schools all have a good working knowledge of the project and its technology – and then leaving behind experienced Bloodhound Ambassadors to maintain communications when the Regional show moves on. The idea is that Gary and the team will have completed the UK operation by the time Bloodhound rolls out to 2012.

The Bloodhound Comms team is making steady progress- and you can see the first Cisco Bloodhound TV items on the website. The plan is for Stefan Marjoram to create these at the rate of two per month so you can see how the programme is developing on a very wide front. In addition the BBC is underway with its Learning Programmes and there will be two Bang Goes the Theory items this year with the first due this month.

At the end of July we managed to present the Informal Education plan to the Education sponsors and this was very well received – thus providing the project with its true global programme and exposure. We restart on all this in earnest when Hugh Greenway returns in September.

And then this week Dr Eric Schmidt CEO of Google lambasted the Brits for the poor Victorian education system – he believes something should be done to reignite children’s passion for Science and technology. The BBC report is here.

This goes right back to the genesis of Bloodhound and the very reason for our existence. There seems to be an awful lot of influential people who believe the British system is just not delivering to international standards. The consequential loss of opportunity to the country could be massive. The way forward is Informal Education where the followers can self educate off the web – and this is our plan so that the global followers of Bloodhound can acquire sufficient knowledge to understand the performance and run data we will be giving them and thus be able to share the project with us.

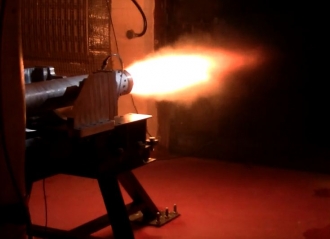

In parallel with all this, the rocket programme is getting itself back on track – John Davis now has the Cosworth CA2010 engine running and pumping using an interim gearbox which allows the pump to run to 10,000rpm, still some 2,000rpm below target, but sufficient to get our full scale test firing together later this year. A huge Health and Safety analysis has been developed with QinetiQ and Chris Boocock our H&S expert from sponsor RIS. In August we ran a 6 inch firing of the development rocket for the BBC and hopefully later this year we will be able to run the huge 18 inch motor using the Cosworth engine powered HTP pump in UK! This is going to be spectacular!

In parallel with all this, the rocket programme is getting itself back on track – John Davis now has the Cosworth CA2010 engine running and pumping using an interim gearbox which allows the pump to run to 10,000rpm, still some 2,000rpm below target, but sufficient to get our full scale test firing together later this year. A huge Health and Safety analysis has been developed with QinetiQ and Chris Boocock our H&S expert from sponsor RIS. In August we ran a 6 inch firing of the development rocket for the BBC and hopefully later this year we will be able to run the huge 18 inch motor using the Cosworth engine powered HTP pump in UK! This is going to be spectacular!

The UK firing will not be at full power yet due to the inability to make full revs on the Cosworth engine. but it will enable us to test run all John Davis's rocket management systems which control the engine and the HTP flow. When the new Xtrac gearbox is with us we can then run the pump to 12,000rpm and work our way through the rocket acceptance trials. That will get us to the point where all we have to do is to start manufacture of the operational rocket cases and establish arrangements for fuel and oxidiser supply. It sounds simple – but there is a very long way to go!

The events team is crucial to the entire programme – Stella Diamond has taken over the management and things move smoothly particularly now that we have a dedicated Mercedes Sprinter Van loaned by Rossett Commercial. Typically the Bloodhound show car is on display 3-4 days every week in different events and the logistics are handled by Graham Lockwood. Demand is growing very strongly now and it looks as if we need a second show car. Already bookings are extending into 2012 and the events team are getting frantic as demand picks up. We are getting constant event conflicts which is a great shame as opportunities are being lost. In parallel Andy Green and I do around 150 project presentations a year and now that we are into build we are having real problems with availability.

Over in Australia, the Aussie Invader R team are making dramatic progress. There is already a great deal of car in evidence and there should be no problem in getting the car operational in 2013, if not before – this is getting very interesting indeed!! Back in the US there is a vague rumour that there could be a challenge in 2012 – this could be magic if this happens. But it really has to happen in 2012 before the 1000mph cars become operational. The North American Eagle team are sorting out run venues so they are getting close also. They have some revisionist criticism to make of the Thrust SSC team using US facilities in 1997 – it is important to put this in accurate context: the ThrustSSC team met all the local operational, financial and legislation criteria and paid for everything - the funds going mostly into the local US economy and resulting in substantial UK project debt which took the exhausted team a very long time to clear and involved selling the project assets. The US Bureau of Land Management gave the ThrustSSC team a major award for their sensitive clearance and husbandry of the desert and all the ThrustSSC technology is still up on the web - see www.thrustssc.com. We are extremely grateful to the very generous local US sponsors who entered into the spirit of the event to help us and to whom we are absolutely indebted for their support. The car still sports crossed US and UK flags on the nose to endorse the US support for the venture which came from our lifetime friends.

The Bloodhound funding is of course always a massive concern – no aerospace company in its right mind commits to a project like this with funding only from sponsorship and public donation. As I write this the funding programme we are running with the Influence agency is really coming good. We have processed a very large number of companies and we are starting to get a stabilised understanding of the response. The companies want global projects and that’s fine because that’s exactly what we set out to achieve and Bloodhound is now being followed in 211 countries. They are beginning to understand that sponsorship is now a mature marketing tool that develops huge interest and passes on the goodwill, interest and connections. They like to use the sponsorships to encourage and enthuse their own employees. But above all they are influenced by Education and this is turning out to be a huge project driver. The rate is working out at 5% ie.1 in 20 of the companies approached for financial participation is keen to take it forward. As it stands at the moment, our commitments are approaching 50% of total budget. And there is no capital in the company – we live on our revenue – it's very very tough!

Another element in all this is outstandingly important operational safety. Unfortunately the land speed record still carries the image of an emotionally charged driver in pursuit of the record taking the vehicle to the edge of its performance and to the brink of destruction. Certainly in the past this made the drivers into huge heroes, but in the process the entire team and sponsors' reputations were uncomfortably exposed and on the line. Of course it had to happen in the past because it was just not possible to model the car performance. When I drove Thrust2 we got to within 7mph of take off - which we didn’t realise until a few hours later!

But the whole Land Speed Record risk changed with the arrival of Ron Ayers and the CFD programme for ThrustSSC in the early 1990’s. For the first time we could model the car performance accurately – and then we could compare actual performance data with prediction. Instead of the engineers being the usual advisory consultants to the driver, who in the past was taking the operational decisions, our engineers could now manage the car development, predict the performance of each run from data and modelling, and the driver would then drive to a safe preplanned run profile.

Suddenly the land speed record became a lot safer. With the modelling technology readily available, there is a duty to employ it and derisk the programme. But of course there is a project duty to reduce risk still further.

At the start of the Bloodhound project we partnered up with the UK Health and Safety Executive – and this was a crucial move. In the past with land speed record projects so much effort had gone into the design and build of the car, that there was often little resource left over for planning and management of the operational side of the record attempt. Today we are moving into rocket propulsion and the operational teamwork has to be very carefully thought through in advance to minimise risk. Working with the Health and Safety Executive, every operational aspect of the car has been worked through in advance with our HSE inspector Rick Brunt. When RIS joined the project they brought Chris Boocock their Health and Safety specialist; Chris quickly adopted the project to help us demonstrate intense commitment to reduce risk at all stages of the project. Chris and the HSE bring a huge asset to the project, its team and its sponsors. Both would leave very quickly if they thought Bloodhound was getting irresponsible and dangerous!

So now it's a battle to complete the build and get Bloodhound onto its wheels, to get the rocket programme through its acceptance trials, to get the education programme running its regional programmes and into informal education. This is a seriously tough call and requires the project to increase its annual revenue by 250%. The whole programme is interlinked and every part is absolutely essential to completion of the programme.

It's a massive challenge – but we now have the car design and the team to achieve this!

So for me I have just a few more peaceful hours on the Arcadia and then it's back to the long days and 1000 miles a week in the VW Golf, which has now racked up over 110,000 Bloodhound miles.

We can do this! A great deal has been achieved! It's just a huge fight now to get the car completed!