This is going to be a difficult diary to write without sounding over-excited. We’ve just launched BLOODHOUND SSC in public and seeing the world’s fastest racing car in once piece for the first time was thrilling. We thought that revealing the Car would be the highlight of the event, but then we were avalanched by 8,000 members of the public over 2 days, all more excited by the Car than we were. It was simply astonishing. The media seemed to think so as well – coverage of the event has generated over £100 million of ‘advertising value equivalent’ (that’s how much you’d have to spend to generate this much global coverage through advertising), adding to the £300 million we’ve already had over the last 12 months. Blimey.

A sell-out event

A sell-out event

Our original plan was to ‘launch’ the Car in public at its first test runs, down at Newquay Aerohub this November. I can now be honest and say that I didn’t really like this plan. I’ve flown RAF jet fighters from Newquay in November (it was called RAF St Mawgan back then) and the weather was mostly horrible. Holding our global reveal in September, indoors at Canary Wharf in London, worked much better.

The big reveal of the launch event was the target date next year for our first World Land Speed Record, 800 mph, as a stepping stone on the way to 1000 mph. The date is Saturday 15 October 2016. This was chosen for a number of reasons – the Car will be ready by then, it’s well before the rainy season starts and it’s after the Olympics.

Sharing an Engineering Adventure

Sharing an Engineering Adventure

BLOODHOUND is all about sharing the ‘Engineering Adventure’, so we also favoured a weekend, when audiences are bigger. The middle Saturday of October seemed an ideal day for our 800 mph runs. It was only when we looked up the date that we realised that it was 19 years to the day after we set the current record of 763 mph in Thrust SSC, back on 15 October 1997. A slightly spooky coincidence, but in a good way.

Ready to go?

Ready to go?

Now that we’ve achieved our public launch, there’s no hurry to get the Car out on the Newquay runway. As a result, the runway test runs will now be held around Easter next year, which is a more logical place in the engineering development programme, and gives us a better chance of good weather. But the Car looks ready to run now, so why wait?

There’s a fair bit of work to do before we can run. We’ve got about 95% of the components that we need to run the Car on the runway, but there are still a few bits that we need to make. In addition, the public launch Car was a ‘hybrid’. The right hand side of the Car was fitted with desert wheels and all the bodywork, as it will be in South Africa next year, while the left hand side of the Car was set up for runway running, with rubber tyres fitted and panels removed for access during initial testing. This is the only time we’ll ever have the Car like this, to give people a chance to see the beautiful lines of a 1000 mph race car and, at the same time, a chance to look inside at all the high-tech magic that makes it run.

It all fits together

It all fits together

The other reason we’re not ready to run yet is that for any race car, or indeed aircraft, the vehicle requires a series of ‘dry builds’ during its development. This is to check that everything fits and works as expected. We also need to figure out how to assemble the Car for running and how to strip it down for servicing. There are a few jobs on any vehicle where you either need double jointed engineers with really small hands, or some specialist tools. The dry build is where you find out how many. For BLOODHOUND, we’re putting together 3500 bespoke parts provided by 340 different companies, so assembling the Car for the public launch this month, with both runway and desert parts, has been really useful. As a summary of the work involved, have a look at the video of ‘building BLOODHOUND in 90 seconds’.

The real magic’s inside

The real magic’s inside

We’re aiming to keep the Car together in its ‘hybrid’ form for few weeks, to give more of our 1K Supporters’ Club members the chance to come and see it at the BLOODHOUND Technical Centre (the 8,000 visitors we had at the launch was the maximum number the venue could cope with – we were sold out!). After that, the Car will be stripped down again, and the full build of the runway car will start, getting ready to go to Newquay next Easter.

For the runway tests, we will be using our EJ200 jet engine from the Typhoon. While I’ve spent a (very exciting) career flying fast jets for the Royal Air Force, I’ve never flown the Typhoon before. As part of my preparation for driving BLOODHOUND, I went up to RAF Coningsby in Lincolnshire to see the EJ200 in its natural environment. Coningsby’s primary role is to maintain 2 fully-armed Typhoons on alert, 24/7, to defend the UK, but they also do all of the Typhoon pilot training. That gave me the perfect opportunity to sit in the back of one of the 2-seat trainers and see the EJ200 engine at work.

Going up

Going up

Quite simply, the Typhoon’s performance is astonishing. A ‘performance take-off’ saw us airborne in seconds, before rotating to punch vertically up through the cloud. Air-to-air refuelling, high-G turns, supersonic acceleration, it was all in a different league to anything I’d seen before. As you can see from this short video, it’s quite a ride.

From the BLOODHOUND point of view, there were a few surprises, all of them good. Engine acceleration and reheat light-up is a little quicker than we have been allowing for, so the Car’s initial acceleration will be better than planned. Precision control of this hugely powerful engine was worrying me a little – there is a warning for new Typhoon pilots that ‘5 mm of throttle movement will give a speed change of over 30 mph’, so I was concerned about precise speed control using BLOODHOUND’s foot throttle.

Power and control

Power and control

In fact, the engine is very easy to control accurately, so we can stick with the same fly-by-wire throttle map that the Typhoon uses. Better still, the engine gives an audible compressor whine (that’s the high-pitched noise you hear when a jet engine winds up). This makes is much easier to find an exact power setting, as I can hear the change in frequency when the engine spools up.

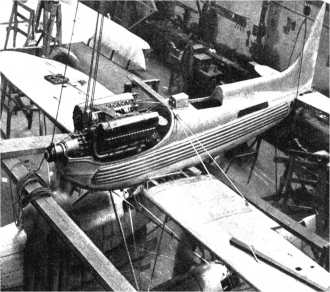

The EJ200 is only the latest in a long list of record-breaking engines from Rolls-Royce. Perhaps the most remarkable engine was the ‘Rolls-Royce R’, a huge V12 supercharged engine (2800 hp!) built to power the fastest aircraft in the world, the Supermarine S6B that won the Schneider Trophy outright for Britain in 1931.

Another record-breaking engine

Another record-breaking engine

The ‘R’ engine went on to win World Land Speed and World Water Speed records in the 1930s, making the only engine in history to hold all 3 outright records. Rolls-Royce subsequently used this expertise to develop the V12 Merlin engine, while Supermarine used their record-breaking S6B experience in developing the iconic Spitfire, powered by Rolls-Royce’s new Merlin engine. Who said that record-breaking never produces anything useful?

It was the 75th Anniversary dinner of the Schneider Trophy, back in 2006, where the idea of BLOODHOUND as an ‘Engineering Adventure’ was born. The technology of aircraft like the Supermarine S6B, and later on the Spitfire, excited and inspired a generation of young engineers. This is the effect we’re trying to create for the young engineers and scientists of the 21st century, by building and sharing the story of the world’s first 1000 mph Car. Based on the public launch this month, we’re making progress. The thing that surprised me most during the launch was the number of people that came up to us just to say ‘Thank you…. Thank you for inspiring us’. That’s what BLOODHOUND is all about. That’s what makes it all worthwhile.