I never fail to be struck by the power of BLOODHOUND to tell its science and technology story. Perhaps this should not be a surprise. After all, we are putting the world’s best military jet engine (from the Eurofighter Typhoon) plus a prototype hybrid rocket system (thanks to Nammo) into the most sophisticated Land Speed Record Car ever. Then we’re aiming to reach a cool 1000 mph. Looking at it this way, it’s a pretty compelling story!

Having fun, learning

Having fun, learning

Our primary audience for BLOODHOUND’s Education Programme is the next generation of young scientists and engineers. We’ve recently totalled up our activities for last year, which directly engaged with around 110,000 students. Based on UK Government figures, this is over £1 million of science education value, and that’s just the stuff we know about. If you haven’t got involved yet, then try one of our model rocket car workshops, they are terrific fun for kids of all ages (our oldest ‘student’ entrant so far was over 80).

At the other end of the scale, BLOODHOUND is providing key research data to the academic world. I was down at the BLOODHOUND Technical Centre last week to meet Professor Hamid Roohani from Witwatersrand University in South Africa. He’s working with BLOODHOUND’s aerodynamicist Dr Ben Evans (of Swansea University), and with our performance expert Ron Ayers, to explore how BLOODHOUND’s extremes of speed and acceleration can affect the airflow around it.

It’s easy to assume that all this has already been discovered. Aeroplanes went supersonic 70 years ago and we went to the Moon almost 50 years ago. Nowadays, everything can be solved by computers, can’t it? Well, in fact, no.

The Million Dollar Question

The Million Dollar Question

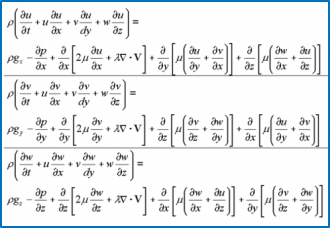

The airflow around cars (and aeroplanes) is governed by the ‘Navier-Stokes’ equations. These equations have been described as ‘one of the 7 most important open problems in mathematics’. It’s called an ‘open problem’ because no-one has managed to prove that a complete solution exists, and there is a US $1 million cash prize for the first person to solve these equations (if you find a solution after reading this, then we’ll share the money).

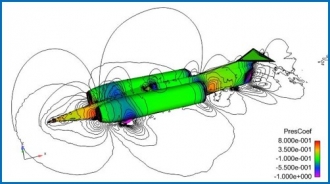

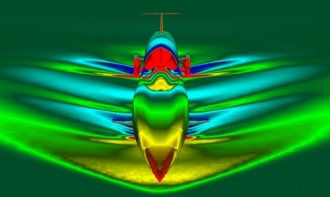

Given that no-one has even found a solution yet, you can see why the computer models are not trusted with the really difficult problems like high-speed turbulence, when the airflow breaks away from the wings/bodywork of vehicles. The best computers can do is to work out an approximate answer, using a technique called ‘computational fluid dynamics’ (or CFD for short), using the power of supercomputers to estimate a solution to the monster problem of Navier-Stokes.

Old school testing

Old school testing

To make up for the limitations of CFD, designers use things like wind tunnels to test the airflow around cars and aircraft. I was amazed to find out last week that most of the Eurofighter testing is still done in wind tunnels, for example. It’s the same in the car racing world and Formula 1 teams still do a huge amount of testing in wind tunnels.

For BLOODHOUND, this gives us both a problem and an opportunity.

Finding new solutions

Finding new solutions

The problem is that we can’t really put BLOODHOUND into a wind tunnel. Supersonic wind tunnels are extremely expensive. Worse still (and here’s the real problem), there is no way to make the ground beneath the Car rush past at up to 1000 mph, so we can’t properly reproduce the flow underneath a supersonic car. That just leaves us with computer modelling and CFD … which I’ve just said are unreliable. Time to review my life insurance policy, or even find another hobby? Not quite. This problem is nothing new for us.

Back in the 1990s, as Ron Ayers wrestled with designing Thrust SSC to be the world’s first ever supersonic Land Speed Record car, he faced the same challenge. He knew CFD was largely unproven and often wildly inaccurate, so he needed a way to validate the computer results. His solution was to validate the computer results by putting a model of the Car (fitted with high-speed pressure sensors) onto a supersonic rocket sled. This would have (to quote Ron) 2 big advantages over wind tunnels. The first was that it would provide ‘real’ results at supersonic speeds over the ground. The second advantage (which I love) is that it would be ‘a lot more fun than wind tunnel testing’!

More fun than a wind tunnel

More fun than a wind tunnel

This unique experiment was hugely successful, as the results from the rocket showed an astonishingly high level of agreement (or ‘correlation’) with the computer predictions for Thrust SSC. Using this breakthrough, he could finalise the shape of what would soon become the world’s first supersonic Land Speed Record Car.

This was also a huge leap forward for the science of CFD, as it showed that the technique could be used to design something as complicated as a supersonic car. With this background, we are feeling very confident about using CFD to model the airflow around BLOODHOUND SSC. Quite simply, we’ve done this before and we know it works. We now have vastly improved computers with far more detailed (and, I’m being promised, more accurate!) airflow models.

The future

The future

This brings us to the opportunity for BLOODHOUND, and the work we’re doing with Swansea University and Professor Roohani out in South Africa. After nearly a decade of detailed design work and CFD, we are now getting ready to run the most sophisticated (and with around 500 sensors, the most heavily instrumented) car in Land Speed Record history. To quote the good Professor, this is a unique experiment which gives him (and Swansea, of course) the chance to validate CFD at high speeds, and at high ‘G’ forces, in a way that has never been done before.

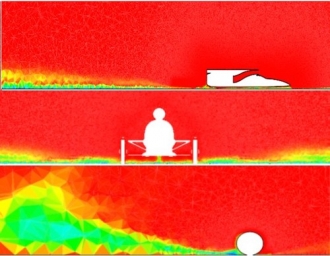

The Professor’s particular area of interest is the acceleration and deceleration effects. To give an example of the effects he is studying, for a ‘normal’ aircraft wing with a chord of one metre (that’s the distance from the front to the back of the wing), an acceleration of one ‘G’ (20 mph per second) will move the shockwave by around 5 cm, i.e. 5% of the chord. As a pilot, I can tell you that 5% is a significant amount in terms of handling and performance.

From my point of view as BLOODHOUND’s driver, this effect becomes more interesting. The Car will accelerate at nearly 2G and decelerate at 3G, so the shock waves may move quite a lot between full-power acceleration and maximum deceleration. Moving the shockwaves will cause the pressure over the bodywork to change, which in turn affects the all-important download on the wheels, so this is important stuff.

Professor Roohani’s research will help us to measure this effect, but this is not the only thing that CFD will be trying to predict. As the front wheels of the Car tear across the surface of our dry lake bed track at Hakskeen Pan in South Africa, the wheels will throw up a lot of dust, which will be mixed (or ‘entrained’) in the airflow around the back of the Car. This entrainment is also likely to have a big effect on the shock waves forming on BLOODHOUND’s bodywork.

Predicting a dust storm

Predicting a dust storm

All this has been modelled using CFD. Now we’ve got a chance to validate the model in a unique way, and in so doing, to help CFD become more accurate and more trusted for future design projects. Once again, we find ourselves at the cutting edge of science in our quest to reach 1000 mph. It’s not just a whole generation of 10-year olds that will be watching BLOODHOUND’s every run with fascination. We’re going to have scientists and engineers all over the world checking our homework in great detail!

Elsewhere in the BLOODHOUND Technical Centre, work continues as we gradually get the Car ready to run. Last week I watched the fuel system being finished, after some final modifications to the Car’s fuel tanks.

Race car tanks are usually packed with ‘open cell’ foam (like a big sponge), which does 2 things. First, the foam stops the fuel ‘sloshing’ in the tanks as a race car repeatedly accelerates, brakes and corners at high G forces. As you can guess, this is not how we plan to operate BLOODHOUND SSC, so it’s not a major concern. The other thing the foam does, though, is very useful. As the fuel level in the tank falls, air is drawn in to replace it and there is a risk that an explosive mixture can be created in the tank. The foam breaks the tank up into thousands of tiny individual air pockets, which removes the risk of an explosion, so we’re fitting it as an additional safety feature.

Fitting foam

Fitting foam

It was great to see Jonathan Tubbs from Advance Fuel Systems finishing our tanks off for the Car’s first runs. Jonathan has been doing this for a long time. I remember helping him and the Thrust team to fit the fuel tanks into Thrust SSC, over 20 years ago. The main reason this sticks in my mind is that the tanks were slightly bigger than the access holes they were supposed to go through. After a very long afternoon and evening’s work, we eventually ended up forcing the last of them into place at 1.30 in the morning. I’m delighted to report that this time round, BLOODHOUND’s tanks all fitted perfectly, no late nights involved, no force required. Another small (and well-fitting) step on the road to 1000 mph.