While we’re working steadily to get BLOODHOUND SSC ready for its first runs, our ‘Engineering Adventure’ continues to captivate young audiences. Part of exploring the science and technology is to do-it-yourself, so it’s no surprise that our Model Rocket Car Challenge is in huge demand.

New World Record coming up….

New World Record coming up….

The idea for this goes back to 2011, when Joseph Leckie Community Technical College set a new Guinness World Record, for model rocket cars, at a very impressive 88.9 mph (you can watch the video here).

That’s almost 90 mph in the school playground! (and yes, they did do a risk assessment first). It was also a huge challenge to every other school out there – and so the competition idea was born.

The BLOODHOUND Model Rocket Car Competition has 4 classes, ranging from Class 1 (under 11s, small rocket, 25m track) to Class 4 (‘Unlimited’: anyone in full-time education, any age, any number of rockets). The Unlimited record now stands at an unbelievable 533.1 mph (well done to the current world record holders, Joseph Whitaker School in Mansfield). Last week I heard that someone is now designing a model to achieve 900 mph – blimey. I’m more convinced than ever that the first ‘BLOODHOUND’ Car to go supersonic will be in a school playground somewhere….

The ‘BLOODHOUND Effect’

The ‘BLOODHOUND Effect’

To understand the effect that this challenge is having on young people, you just have to listen to them. A young lady called Zoe, part of the Joseph Whitaker team (World Record holders!) summed it up: ‘I want to get into engineering in the future….I’d heard about BLOODHOUND and was watching BLOODHOUND over and over again on YouTube. I think everyone’s going to be watching [the record attempt] – it’s going to be amazing.’ That’s the ‘BLOODHOUND effect’ in action.

The Rocket Car Experience

The Rocket Car Experience

Over the Christmas and New Year holidays, we ran a number of ‘Rocket Car Experiences’, to give our young supporters a taste of model rocket car racing. These one-day events included a tour of the BLOODHOUND Technical Centre to have a look at the real thing, before building and racing your own rocket car. Not surprisingly, we were hugely over-subscribed, with over 400 ‘young’ visitors (the oldest was actually 87) coming to see us.

Thanks to the huge demand we’re now holding Rocket Car Experiences during every school holiday, run by the tirelessly enthusiastic Rob Bennett (on behalf of the hundreds of young people you’ve excited and inspired already, thank you Rob). Want to give the kids (and yourself!) a really fascinating day out and have some fun as well? You can book here for the next one in February.

A few months ago we invited a well-known motoring magazine to come and take part in one of our Rocket Car Challenge days, at Pimlico Academy. To give them a good chance, we sent them a kit of parts (wheels, axles, foam block for the body, etc.) several days in advance. Despite this, the journalist turned up on the day with a ‘finished’ car that looked like a house brick on wheels.

In pursuit of speed

In pursuit of speed

Looking round at all the carefully thought-out and well-engineered solutions from the pupils he was going to be racing, this distinguished journalist was heard to mutter ‘Oh dear, I think I’ve rather underestimated this one’. Indeed he had. The AutoCar effort (yes, it was them) was a good 20 mph slower than the winning student car. To give AutoCar some credit, the magazine is keen to have another go…

Like Land Speed Racing, the Model Rocket Car challenge seems simple enough at first glance. Take a block of modelling foam, 2 axles, 4 wheels. Design and make your optimum chassis shape. Attach the wheels and the metal loops for the guide wire (a key safety feature – not all of these cars run dead straight!). We then fit a small ‘Estes’ rocket into the pre-drilled hole in the back end of the chassis, attach the battery wires, press the button and….whooosh. Anything between 29 and 53 mph, based on the groups we had recently.

This seems like a big speed range, so what makes the difference between a journalist-designed house brick and a 50+ mph winner? There’s a lot to think about, which is what makes the challenge so interesting. Thrust, mass, drag and stability all make a difference, just like the real Land Speed Record.

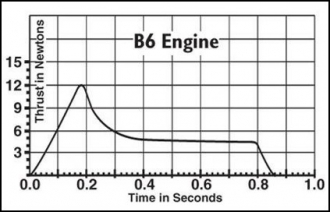

First the thrust. It’s the same fixed amount for all the cars: for the ‘Rocket Car Experience’ days, we use the BLOODHOUND Challenge ‘Class 2’ regulations, with a 50 metre wire and a ‘B6-0’ Estes rocket. The thrust curve for the ‘B’ rocket shows the rocket burning for about 0.85 seconds, which is when the car’s speed is at its peak. In theory, the fastest car will be the one that hits the time trap just as the rocket motor burns out. In practice we use a radar gun, which measures the peak speed over the last few metres of the run, so we can largely ignore the thrust profile.

6 Newton-seconds of ‘WHOOOOSH’

6 Newton-seconds of ‘WHOOOOSH’

The mass of the model is much more important. The lighter the model, the faster the car will accelerate and the higher the peak speed. For example, a mass of 200 g under the average rocket thrust of 6 N will give you an acceleration of 3 G (3 times the force of gravity, which is the equivalent of 0-60 mph in one second). If you can reduce the mass of the vehicle to 150 g then you’ll get a 4 G acceleration – much better. There is a limit to how much foam you can cut away, though. To quote Mark Chapman, BLOODHOUND’s Chief Engineer, ‘The trick is to find the right balance between strength and lightness’.

Of course, a theoretical 3 G acceleration (60 mph in one second) will not get you anywhere near 60 mph, because your other big enemy is drag, which can (and will) reduce the acceleration dramatically. For example, the shape of the car will affect the aerodynamic drag.

Keep it thin, keep it stable

Keep it thin, keep it stable

If this doesn’t seem important, try putting your hand out of a car window at 60 mph, and compare the (high) drag force when your hand is flat to the wind and the (much lower) force when it’s edge-on. This drag effect will make a big difference to the way your lightweight rocket car runs.

To make it bit more complicated, aerodynamics is not the only source of drag. The wheels and axles are another key area. If you just poke the axles through the foam block it will work after a fashion, but if you use axle tubes (plastic drinking straws, for instance) it works soooo much better.

The other thing to think about is stability. If the car is running dead straight, barely touching the guide wire and skimming across the ground, it will be going as fast as it can. Bouncing around, or having crooked wheels pulling off to one side, will waste a lot of energy. Stability is a huge and complicated subject, often best solved by trial and error. Will a tail fin make your rocket car more stable? Try it and find out!

Given the fixed thrust, what is the most important – drag, mass or stability? The simple answer is mass (but don’t tell anyone else, this is your race-winning secret). For the very short burn time of the Estes rocket, acceleration is affected more by mass than anything else, so get carving, you’ve got to get rid of a fair chunk of foam block (journalists: please note for next time!).

Extra mass is not your friend

Extra mass is not your friend

If mass is so important, then why aren’t we trying to make BLOODHOUND SSC as light as possible? For Land Speed Record cars, there are a couple of important differences. With much higher speeds, the drag factor is much higher. BLOODHOUND is planning to travel at 1000 mph, about 20 times as fast as a model rocket car. Drag goes up with the square of the speed – so the drag will be about 400 times higher at 1000 mph than it is at 50. Hence keeping the drag low for BLOODHOUND SSC is more important than being very light. Stability and structural strength are also vital, so we need to have a Car that is built to take the most extreme loads it will encounter, with a big safety margin. Speaking as BLOODHOUND’s driver, this is really important.

This balance of thrust vs strength vs mass is the challenge faced by all Land Speed Record teams. I saw an interesting figure recently, about the mass of the engine vs the mass of the whole car, which I’m still thinking about. Since 1963, the fastest cars have all been jet powered, with some very different designs, ranging from the single-engined American cars of the 1960s to the twin-engined 10-tonne monster Thrust SSC, which still holds the record today (but not for much longer…). Surprisingly, given how different all these cars were, the jet engine(s) make up roughly 30-40% of the car’s mass, seemingly regardless of shape or design.

Finding the balance

Finding the balance

Is this a design facet of jet-powered record cars, or just a coincidence? I’m not sure. What surprised me was doing the same sum for BLOODHOUND SSC. BLOODHOUND will weigh in at about 6300 kg empty, including 1200 kg of EJ200 jet engine and 1000 kg of rocket system, which makes a total of… 35% of the Car’s mass. That’s the same as many of the previous cars, but there’s one big difference. BLOODHOUND is designed to do 1000 mph, and going this much faster requires a much stronger chassis and bodywork, which (you might reasonably expect) would be heavier.

The surprise is that BLOODHOUND has kept that same mass ratio as previous generations. The BLOODHOUND engineers have done a remarkable job of finding Mark Chapman’s ‘balance between strength and lightness’. At the same time, they are doing something perhaps more important – they are helping to share their ‘Engineering Adventure’ with the next generation.