Earlier this month I was speaking to a British Airways audience at their annual flight safety day. My aim was to tell them how we set the first-ever supersonic record back in 1997, with Thrust SSC, and to talk about how we planned to get to 1000 mph with BLOODHOUND, safely. It was also a useful chance for us to show our homework to a group of industry safety specialists – in this case 200 commercial pilots and aircraft engineers. If there is something that we haven’t thought of yet, they will find it! From my point of view, this is one of the great strengths of Project BLOODHOUND. The more expert advice we have, the more confident we can be that we’re going in the right direction.

As I told the BA group, the requirements for a safe Land Speed Record are really very simple:

1. Keep the Car shiny side up.

2. Stop before the end of the track.

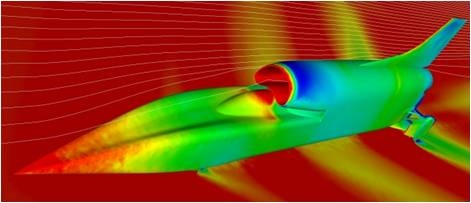

Keeping the Car shiny side up is primarily an aerodynamic problem and, after 6 years of research, we remain confident about the shape that we’ve developed. Our aerodynamics engineer Ben Evans gives a great summary of this 6 year marathon in ‘The Path to Predictability’. As he points out, we’ll be testing the aerodynamics on every run, and only going faster when we know that the Car will stay on the ground.

Stopping is compulsory

Stopping is compulsoryStopping the Car is slightly different. For the whole time that the Car is accelerating, I can always throttle back if something doesn’t look right: more speed is always optional. However, when the Car comes bursting out of the measured mile at over 1000 mph, slowing down before the end of the track has just become compulsory. The end of the track may be 5.5 miles away, but the Car is doing a mile every 3.6 seconds, so that’s really not very far.....

Getting this bit right is so important that BLOODHOUND, uniquely, has 3 different options for stopping. The first is jet fighter-style airbrakes, which can be deployed gradually from 800 mph. Alternatively (or if there’s a problem), we’ve got a brake parachute that will generate about 9 tonnes of drag at 670 mph. And if there’s a problem with the chute, then we’ve got a second identical brake chute, just in case.

James, Jon and Slider

James, Jon and SliderThe airbrake mechanism is squeezed under the jet engine. Clearly both sides must deploy at the same rate, otherwise I will rapidly be going round in circles. Twin hydraulic pistons drive a single slider plate, which in turn is connected to both airbrake doors so that both move together. If that is difficult to picture, then have a quick look at the airbrake animation on the BLOODHOUND website.

Thanks to another great piece of work by URT, the finished slider has just been delivered to our Technical Centre in Bristol. Want to come down and see it for yourself? Join our 1K Supporters’ Club and we’ll invite you down for one of our open days.

Hydraulic Airbrake Control

Hydraulic Airbrake ControlKey to stopping the Car from 800 mph with the airbrakes is getting them to deploy at the right rate. Too fast, and we’ll overstress and damage the doors. Too slow and we won’t stop quickly enough. In addition, they need to be ‘fail safe’ – in other words, if we lose electrical or hydraulic power on the Car, then the airbrakes need to deploy automatically (because slowing down is still compulsory, even if you’ve got problems).

This is where Parker Hannafin comes in. We’ve just received 3 hydraulic control blocks from Parker, which will take care of the airbrake deployment, at the right rate, with or without power. One less thing to worry about.

Brian checking the Wishbones

Brian checking the WishbonesThe suspension components are still arriving at Bristol, with the front upper wishbones recently delivered by 4Front Racing. These are fabricated in steel, in multiple parts, and then welded, heat treated and ground. The upper wishbones transmit the front wheel loads to the chassis, so they’ve got a lot of work to do. We only need a few more suspension bits before we’ll be able to conduct the first test-build of the whole front suspension.

The front suspension assembly bolts onto the front of the cockpit monocoque. The inside of the cockpit is now being fitted out, while the PPA Group is making the first of our cockpit windscreens. The screen is made in layers and then bonded together, with each layer formed from a block of solid acrylic which is heated and stretched.

Optical Perfection in the making

Optical Perfection in the makingThis ‘stretched acrylic’ is the same as that used for jet fighters like the Typhoon, and makes the screen far more resistant to large impacts, like a bird strike. BLOODHOUND is using a 25 mm thick screen, which is just a little thicker than the Typhoon. As we’re going faster at ground level than any jet fighter in history, a thicker windscreen makes sense. The extra thickness should allow the BLOODHOUND to survive the impact of a one kilogramme bird at 1000 mph. I really hope we don’t have to test that for real.

The 25 mm screen sits just in front of BLOODHOUND’s jet engine intake, and shapes the supersonic airflow before it gets there. The angle of the screen is very shallow, to generate the right shockwave pattern, and this oblique angle means that I’ll be looking through over 50 mm of solid plastic to see where I’m going. The screen will need to be optically perfect, so this first sample is an important test of the process.

5.3 kg of racing support

5.3 kg of racing supportFurther back in the Car, the jet engine relies on an ‘airframe mounted accessory drive’ or ‘AMAD’ gearbox. The AMAD contains the engine starter turbine, as well as the electrical generator and hydraulic pump that will power BLOODHOUND. All of this will be supported by the AMAD bulkhead, which weighs only 5.3 kg and will be supporting over 100 kg of gearbox and systems. BLOODHOUND engineering is like a normal race car but with everything multiplied everything by 10.

Fancy a Ride?

Fancy a Ride?At the back of the Car, works continues on the Fin. While the final parts are being released for manufacture, we’ve had a test piece made for one of the intercostals (internal ribs). Here again, keeping the weight down is important, so the intercostal is only 2 mm thick. Extra tooling holes and close-formed plugs have meant the part has remained stable under machining and has come out to exactly the shape of the drawing. Having proved the manufacturing process, we can now start making the other 200 parts of the Fin in earnest. A mixture of motor sport companies will work on the small parts, while aerospace expertise will deliver the big bits, for the hardest working fin in history.

We’re also just about to exceed 20,000 names on the tail fin. Want to join us at 1000 mph? Put your name on the fin and you can!