2015: From This…

It’s remarkable to look back at the progress we’ve made over the past 12 months. At the start of the year, we had the ‘1000 mph model kit’ laid out on the floor of the BLOODHOUND Technical Centre. Less than 12 months later, we’d completed the first ‘dry build’ of our runway test car and held the launch in London, to huge public and media acclaim.

…To This

…To This

From a personal point of view, I’m feeling ever more confident about how all the different technologies will work together in the world’s first 1000 mph Car. We’ve also got plenty of technical evidence to support this feeling. Our various test programmes have delivered some great results over the past 12 months, giving us all the confidence that we can do this, and do it safely.

Fitting the jet engine

Fitting the jet engine

As ever, there are still a lot of technical challenges to overcome (that’s what an ‘Engineering Adventure’ is all about!) and, of course, there’s the ever-present challenge of funding our hugely ambitious attempt to inspire a generation with the magic of technology, but after an amazing 12 months, we’re getting there.

Looking back, I’m struggling to point to a single highlight for 2015, as there were so many exciting moments. Perhaps one of our big achievements was the completion of the chassis, making the Car look nearly ‘finished’ for the first time.

It seems a very long time ago that we were examining the upper chassis, after adding 11,500 rivets and then heating to 175 deg C in an autoclave (i.e. cooking it in a big oven) to set the bonding agent (glue).

World-class Typhoon power

World-class Typhoon power

Once the upper chassis was complete, we fitted the EJ200 jet engine into it for the first time. BLOODHOUND suddenly started to look like a Car getting ready to do something.

One of the highlights of 2015 for me was getting to see the EJ200 working in its ‘natural’ environment, when I flew in the back of a Typhoon jet fighter. The power and control of the engine was simply amazing, confirming that we have made absolutely the right choice for BLOODHOUND.

The world’s fastest Fin

The world’s fastest Fin

Another hugely complex area was the world’s fastest Fin. At 1000 mph, BLOODHOUND is aiming to travel faster than any jet fighter has been at ground level, ever. To do that safely, it will need to have some of the strongest bodywork ever made, plus the hardest working aerodynamic fin in history to keep it straight. We were lucky to have the support of 71 Squadron Royal Air Force, the MOD’s aerospace repair specialists, to help us with the fabrication and assembly of this ‘super Fin’.

BLOODHOUND’s Fin is still proving hugely popular with the public. We’ve now got over 30,000 people who are supporting the Project by putting their names on the Fin. If you want your name to travel at over 1000 mph one day soon, then join them here.

Getting the rocket system ready for testing is still proving to be a game of 2 halves. That’s not a surprise, really, as this is new prototype technology – it really is rocket science. We’ve sorted out the problems with the hydrogen peroxide (HTP) pump and it’s now ready to test. Meanwhile, the specification of the first rocket pack to go into the Car is still being tweaked (the technology really is that new), which is part of what makes this exciting.

Fun AND inspiration

Fun AND inspiration

We’re not the only ones getting excited about rocket technology. The schools model rocket car challenge was launched this year and is proving hugely popular. Our rockets have also kept a lot of young people busy over the Christmas holiday, with the BLOODHOUND rocket car days at the Technical Centre rapidly selling out. We had to run extra events to cope with the demand, so a big thank you to all those who came down after Christmas to help out.

One of the fun bits of 2015 was taking racing driver and TV presenter Chris Harris flying, to mimic the ‘G’ profile for a 1000 mph run. Chris found it hard work in places, as you can see from his YouTube video. The flying sequence starts at 32 min, but watch all of it if you have time, it’s a really good piece (apart from where he describes us all as ‘genius wallies’, I’m still not sure about that bit). I’ve heard a rumour that Chris might be one of the new Top Gear presenters. If that’s true, let’s hope he gives the occasional mention to properly fast (i.e. supersonic) cars, as well as all the boring slow track stuff!

Mobile rocket replenishment

Mobile rocket replenishment

In the past couple of months we also started to consider how we would operate BLOODHOUND SSC. This requires support equipment (refuelling, towing, hydraulic power, etc.) and a comprehensive set of checklists for the start up and shut down of the vehicle.

I’m still working on the Driver’s Notes and Checklist, but I’ll aim to publish the first working draft soon. In the meantime, it’s great to see some of the support equipment being finished off, with the steadfast help of the Army’s REME technicians.

8 billion laser points

8 billion laser points

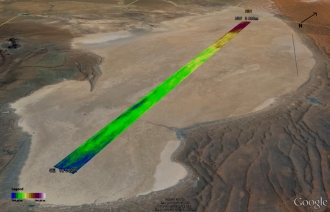

One other highlight of 2015 for me was completing the most advanced survey of a Land Speed Record track ever attempted. The laser scan of our Hakskeen Pan track, in the Northern Cape of South Africa, yielded 4 billion laser points covering 8 million square metres of dry mud lake. We’re analysing the resulting digital elevation map of the track, to predict suspension loads, frequencies, and so on.

We’ll probably still be learning from the scan after we’ve finished running the Car, there’s just so much information to understand. The summary is the important bit though – we’ve got a world-class track for the world’s fastest car. Now all we have to do is get it running.

Here’s wishing you all a supersonic 2016!